|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

force carrier from housing, in some instances it may be

necessary to break carrier loose from axle housing by striking

the carrier with a heavy soft hammer (lead, plastic, rubber or

leather). Be sure that the differential is securely supported on

a portable floor lift before it is separated from the housing.

DISASSEMBLY

Mount differential assembly in a suitable holding fixture.

Remove Differential and Drive Gear Assembly

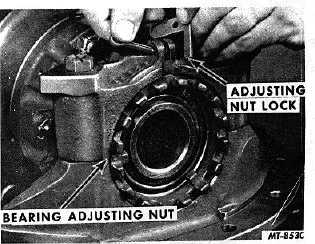

1. Remove cotter pins from bearing adjuster locks

and remove locks from bearing caps, Fig. 9.

Fig. 9 Adjuster Lock Removal

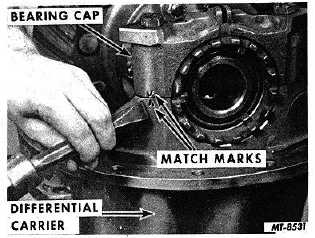

2. Match mark one differential bearing cap and leg

of carrier with punch or chisel, Fig. 10, to identify

each for correct reassembly.

Fig. 10 Marking Bearing Cap for Identity

3.

Remove bearing cap stud nuts or cap screws and

take off the bearing caps and adjusting nuts.

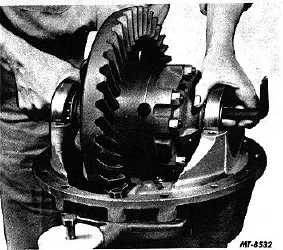

4.

Tip differential away from pinion and lift assembly

out of the differential housing, Fig. 11.

Fig. 11 Lifting out Differential and Gear Assembly

Disassemble Differential Case and Gear Assembly

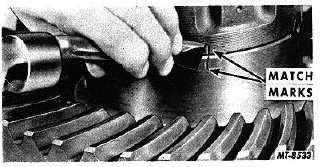

1.

Match mark differential case halves, Fig. 12, with a

punch for correct alignment on reassembling.

Fig. 12 Marking Differential Case Halves

2.

Cut lock wire and remove capscrews or stud nuts to

separate case halves, Fig.13.

NOTE

Some differential assemblies use self-locking

capscrews and nuts.

3.

Remove spider, pinions, side gears and thrust

washers, Fig. 14.

4.

To remove drive gear rivets, carefully center punch

each rivet head. Next use a drill .8 mm (1/32")

smaller than body of the rivet and drill through rivet

head, Fig. 15. Use a

CTS-2095S-CHAPTER I-Page 6

PRINTED IN UNITED STATES OF AMERICA

|