|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

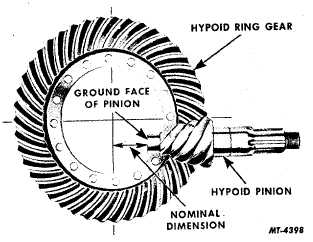

hypoid rear axles actually have a greater torque capacity than

do the spiral bevel type. This is possible because the hypoid

pinion is larger in diameter and has gear teeth that are larger

than those of the spiral bevel pinion having the same number

of teeth and same diameter ring gear. Hypoid pinions also

have larger tooth areas and more teeth in longer contact with

the ring gear. These design characteristics contribute to

greater strength and quieter final drive operation. However,

because of this greater tooth contact, more attention is

required when securing a correct pinion setting at time of

overhaul or when replacing differential bearings. Therefore,

every effort must be made to be sure the final setting results

in the best possible tooth contact.

Fig. 3 Hypoid Type Drive

Axle Shafts

Many axle failures can be attributed to the axle shafts;

therefore, it is most important that shafts be installed

correctly, be of correct size and length for splines to engage

fully, have wheel bearings adjusted properly, and be kept free

from runout or bends.

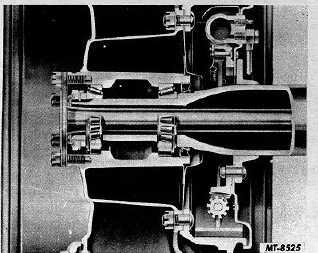

Fig. 4 illustrates the axle shaft and bearing arrangement on a

full-floating rear axle.

Axle Housing

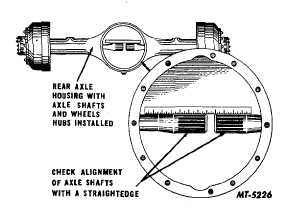

In most cases the axle housing used for IH trucks is of one

piece construction with opening in center for mounting the

differential and carrier. The outer ends of the axle housing are

welded in place to provide mounting for the brake backing

plates. A bent axle housing can be the cause of early axle

failure, and whenever an axle is rebuilt, this condition should

always be checked before going ahead with the assembly.

Fig. 5 gives a quick way of checking for a bent housing.

Fig. 4 Cross Section of Full-Floating Rear Axle

Fig. 5 Method of Checking For Bent Axle Housing

REMOVAL PROCEDURES

Axle Assembly

Whether the complete axle assembly will have to be removed

from the truck for overhaul is determined by the extent of the

repairs required. For most axle repairs complete removal of

the axle will not be necessary; but in the event that it is,

removal procedure will be similar to the following:

1.

Jack up truck until load is removed from springs and

place blocks under frame to safety secure truck

weight off of rear wheels.

2.

Drain differential housing.

3.

Disconnect brake lines and parking brake cables

(where used).

CTS-2095S-CHAPTER I-Page 4

PRINTED IN UNITED STATES OF AMERICA

|