|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

DESCRIPTION

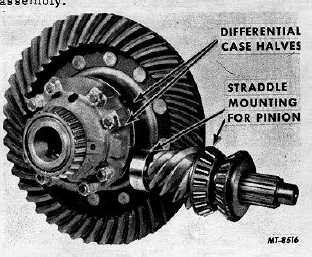

The various axles contained in this section are full floating,

single reduction units. Fig. 1 illustrates the single reduction

differential assembly.

Fig. 1 Differential Assembly

The construction of rear axles may vary as to design, but the

fundamental components of the axles perform similarly

regardless of the type. The basic parts of the axle with which

the serviceman will be concerned are the drive gears, the

differential assembly, the axle shafts, and the housing.

MAINTENANCE

Lubrication

The most important item of axle maintenance about which the

truck operator must be concerned is lubrication. For this

reason factory recommendations on lubrication intervals,

methods of filling, lubricant levels, draining and type of

lubricant must be followed to assure long life and satisfactory

performance. Inspect the axle frequently for lubricant

leakage, especially around housing covers, pinion oil seal

retainer and axle shaft flanges. When necessary, change

gaskets or seals and keep nuts or bolts tight. See

"Lubrication" section in the Operator's Manual provided with

each truck.

Axle Housing Breather Valve

To prevent a pressure build-up in the axle housing when the'

axle becomes warm after a short period of operation, a

breather valve, Fig. 2, is provided in rear axles. Without this

valve the resulting pressure could force the axle lubricant past

the rear wheel oil seals and

damage the brake linings. The valve is so constructed that

warm air may pass out of the axle to relieve built-up pressure,

yet dirt and moisture are prevented from entering.

The breather valve should be kept open and clean. When the

truck is operated off highway on unimproved roads or in ice

and snow, dirt may sometimes be forced under the valve cap

and cause the valve to become ineffective. Remove valve

occasionally and clean thoroughly in a cleaning solution.

Fig. 2 Location of Breather Valve in Axle Housing

Alignment

The rear axle should also be checked at regular intervals to

determine if there is any misalignment of the axle with frame

or drive line. Evidence of misalignment may sometimes be

noted at the U-bolts. To check for axle misalignment, lay a

straightedge across and at right angles to the truck frame.

The straightedge should be longer than the axle tread and

clamped to the frame a short distance ahead of the rear axle.

Measure the distance between the straightedge and identical

points at each end of the axle assembly. When distances are

not equal, misalignment is indicated, and rear springs and U-

bolts must be checked for correct assembly.

Drive Gears

These IH rear axles have the hypoid type of drive as illustrated

in Fig. 3.

Because of the offset type of construction,

CTS-2095S-CHAPTER I-Page 3

PRINTED IN UNITED STATES OF AMERICA

|