|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

16.

Drive the pinion assembly from the companion flange

with a soft hammer. Do not allow pinion assembly to fall.

17.

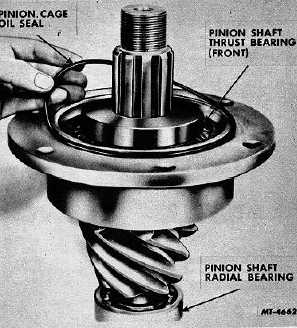

Remove pinion cage "O" ring type seal (Fig. 7).

18.

Tap pinion from cage and remove forward thrust

bearing.

19.

Remove the thrust bearing spacer from the pinion

shaft.

20.

If it is necessary to remove the rear thrust bearing or

the radial bearing from the pinion shaft; remove these

bearings with a suitable puller.

Fig. 7 Removing Pinion Cage Oil Seal

CLEANING, INSPECTION AND REPAIR

Remove all dirt, old lubricant and gasket material from

components of the front axle. Immerse in cleaning solvent and

use a stiff brush if necessary. Bearings should be cleaned

separately in clean solvent and special efforts taken to protect

their finely machined surfaces. If compressed air is used for

drying, do not spin bearings while drying.

Never use anything but brake fluid to clean

hydraulic brake cylinders.

Examine all bearings for roughness, damage to wear

by rotating each bearing

slowly in the hand. If in doubt as to bearing condition,

replace. Ring gear, drive pinion, differential pinions and any

other gears should be checked for damaged teeth, worn

spots, or distortion. Inspect differential case assembly for

cracks, damage or distortion. Make sure splined ends of axle

shafts are neither twisted or cracked. Shim packs should be

of uniform thickness. Discard thrust washers and obtain new

even when only slight wear is indicated. Always use new

gaskets. Hex nuts and capscrews with rounded corners, all

lockwashers, seals, pins and bushings should be replaced.

REASSEMBLY

Differential

The principal adjustments made on the differential

carrier assembly are devised for establishing the proper gear

tooth contact and thereby obtaining a long wearing, quiet

running front axle. Fundamentally, there are five adjustments

to be covered and these are accomplished as the differential

carrier assembly is assembled. To emphasize their

importance these five steps or adjustments are listed here as

well as in the actual assembly procedure. These adjustments

are:

1.

Preload the pinion bearings.

2.

Establish the pinion nominal dimension.

3.

Set gear lash.

4.

Preload the differential bearings.

5.

Check the gear tooth contact.

Refer to the exploded view (Fig. 8) and reassembly

differential carrier as follows.

1.

Press rear thrust bearings (6) firmly against shoulder of

pinion shaft (12).

2.

Press radial bearing (13) on stub end of pinion shaft

(12) and against pinion. Stake face of pinion evenly in six

places to secure radial bearing in place (Fig. 9).

CTS-2658S Page 5

PRINTED IN UNITED STATES OF AMERICA

|