|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

CHAPTER 1-WHEELS, RIMS

Road

failures

are

generally

caused

by

either

overloading or oversight in the maintenance program. To

save hours of downtime a simple visual check of the following

components should periodically be made.

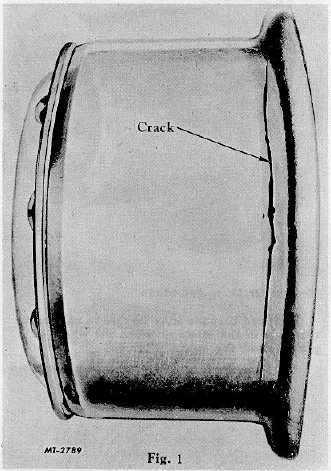

Cracked Rims

Cracked rims or flanges are a result of metal fatigue or

overloading, thus periodic inspections should be made to

assure safe operations, Fig. 1.

Fig. 1

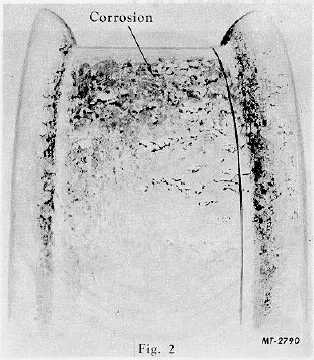

Rim Corrosion

Corrosion is occasionally found on both tubed and

tubeless type rims, Fig. 2. If the corrosion is minor a wire

brushing or buffing' will clean satisfactorily. The tire mounting

surfaces of the rim can then be painted with a good quality

frame enamel or coated with a non-water suspended

lubricant. If corrosion is excessive, fatigue cracks may have

developed in the rim base or the ring may not be

seating in the gutter. The wheel in this case should be

replaced.

Fig. 2

Damaged Or Cracked Rings

Broken or cracked rings are generally caused by rough

use of tire tools or improper initial seating in the rim gutter.

Bent or sprung rings are caused by rough or improper

removal, and cannot be properly reformed to seat accurately

in the rim gutter. They should be replaced, Fig. 3. When

removing the rings they should be worked off in small steps,

starting at one point and gradually working in one direction

around the entire circumference.

Fig. 3

CTS-2167N Page 3

PRINTED IN UNITED STATES OF AMERICA

|