|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

TRANSMISSION

Parts that have been cleaned, dried, inspected and are to

be immediately reassembled should be coated with light oil to

prevent corrosion. If these parts are to be stored for any

length of 'time, they should be treated with a good rust

preventive and wrapped in special paper or other material

designed to prevent corrosion.

Repair

Replace all worn or damaged parts. Hex nuts with

rounded corners, all lockwashers, oil seals and gaskets

should be replaced at the time of overhaul.

Use only genuine International replacement parts for

satisfactory service. For example, using gaskets of foreign

material generally leads to -mechanical trouble due to

variations in thickness and the inability of certain materials to

withstand compression, oil, etc.

Remove nicks, mars and burrs from machined or ground

surfaces. Threads must be clean and free to obtain accurate

adjustment and correct torque. A fine mill file or India stone is

suitable for this purpose. Studs must be tight prior to

reassembling the parts.

When assembling component parts use a press

where possible.

Tighten all nuts to correct torque. :(See torque limits

following service instructions.) Use soft iron locking wire to

prevent possibility of wire breakage.

The burrs, caused by lockwashers, at the spot face of

stud holes of cages and covers should be removed to assure

easy reassembly of these parts.

ASSEMBLY

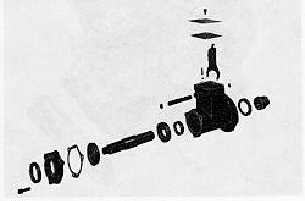

Assembly of Power-Take-Off

Fig. 21.

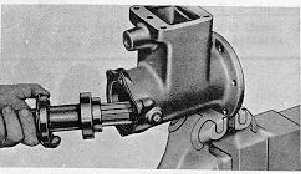

Fig. 22.

1.

Install ball bearings on power-take-off shaft.

2.

Position wiper against inner bearing. Install snap ring in

groove of outer bearing.

3.

Slide shaft assembly into housing and install sliding

clutch on inner end (Fig. 22).

4.

Position a new gasket and install oil seal cage assembly.

Secure with capscrews and lockwashers.

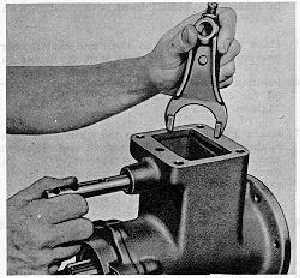

5.

Place shift fork in groove of sliding clutch. Slide shift shaft

into bore of fork (Fig. 23).

6.

Line up recess in shaft with set screw and tighten screw.

Lock wire the set screw to fork.

7.

Install expansion plug in shist shaft hole. If necessary,

replace shift shaft oil seal located in front of housing.

Fig. 23.

CTS-2048Q Page 9

PRINTED IN UNITED STATES OF AMERICA

|