|

| |

TM5-4210-229-14&P

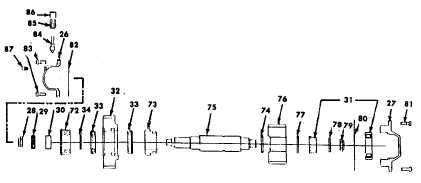

6-18.

TRANSFER CASE REPAIR (Continued).

(13)

Coat the seal surface and the splined

hole of the rear output companion flange with

Lubriplate (Appendix D, Item 34), then install

flange. Lightly coat one side of the retaining

washer (68) with sealant (Appendix D,

Item47) and then install the coated side next

to the companion flange. Install the locknut

(69) and torque it to 300 ft-lb (406.80 N.m).

(14)

Temporarily install the rear output shaft front

cover (35) without shims (70) and torque bolts

(71) to 25 ft-lb (33.90 N.m). Measure the gap

between the cover (35) and the case housing.

Select a shim stack that is 0.010 to 0.005 inch

larger than the gap dimension measured.

Remove the bolts (71) and the cap (35) and

then install he selected shims and reinstall the

cap. Coat the bolt threads with sealant

(Appendix D, Item 47), install and torque

bolts (7 1) to 45 ft-lb (61.02 N.m).

d.

Intermediate shaft assembly.

(1)

Install the double row ball bearing (72) in the

housing bore opposite the large opening at

the rear of the case. Temporarily retain the

bearing with a bolt and washer.

(2)

Insert the alignment tool through the bearing

with the tapped end toward the inside of the

case.

(3) Put the bearing spacer washer (34) in place

onto the alignment tool on the inside of the

case. Place the underdrive driven gear (32)

and bearing assembly (33) on the alignment

tool. Insert the sliding clutch (73) into the

engaged position inside the underdrive driven

gear (32).

(4) Install the split retaining ring (74) into the

groove on the intermediate shaft (75).

(5) Insert the shaft through the large opening on

the back of the case. Align shaft with clutch

splines and engage the end of the shaft with

alignment tool. Screw the tool and shaft

together and then pull the shaft through the

bearings. Once the shaft is pulled through,

remove the alignment tool. Install the spacer

tube (30), speedometer(29), and locknut (28)

on the end where the alignment tool was

removed.

(6) Put the direct drive gear (76) onto the shaft

with the chamfered spline side toward the front

of the case so the chamfer will fit upon to the

split retaining ring (74).

(7) Install the spacer washer (77) and the roller

bearing inner race (3 1) on the shaft. Make

sure the shoulder on the race is toward the

gear to allow the cover and the bearing outer

race and roller assembly to fit over the inner

race.

(8) Install the retaining washer (78) and lock-nut

(79) on the shaft. Torque the nut (28) on the

speedometer gear end to 175 ft-lb (237.30

N.m) while restraining the nut on the opposite

end of the shaft.

(9) Torque the rear locknut (79) to 300 ft-lb

(406.80 N.m) while restraining the front output

yoke

from

turning.

6-101

|