|

| |

TM5-4210-229-14&P

6-18.

TRANSFER CASE REPAIR (Continued).

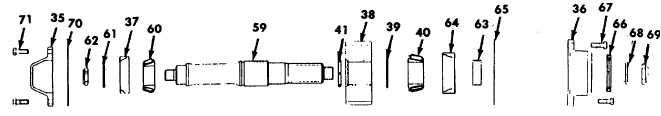

(2) Slip the front bearing (44) over the end of the

shaft and into the housing bore. The bearing

snapring should be on the outboard side of the

bearing. Tap bearing into place.

(3) Install the front output seal carrier gasket (52) and

the seal carrier (42) with the seal (53) in place.

Apply sealant (Appendix D, Item 47) to bolt

threads, then torque bolts(54) to 45 ft-lb (61.02

N.m).

(4) Coat the seal surface and the splined hole of the

front output yoke with Lubriplate (Appendix D,

Item 34).

(5) Align the yoke onto the shaft and tap it into place.

Lightly coat one side of the yoke retaining washer

(55) with sealant (Appendix D, Item 47) and then

install the coated side next to the yoke. Install the

locknut (56) and torque it to 300 ft-lb (406.80

N.m).

(6) Temporarily install the rear cap (43) in place

without shims (57). Torque bolts (58) to 25 ft-lb

(33.80 N.m). Measure gap between the case

housing and the flange of the cap (43). Select a

shim stack that is 0.010 to 0.15 inch larger than

the gap dimensions measured. Remove the bolts

(58) and cap (43) and then install the selected

shims and reinstall the cap. Coat bolt threads

with sealant (Appendix D, Item47), install and

torque bolts (58) to 45 ft-lb (61.02 N.m).

(7) Make certain the bearings are pulled tight against

the shaft shoulders and that the shaft rotates

freely, do this by spinning the shaft.

c.

Rear output shaft assembly.

(1) Install the split retaining ring (41) onto the shaft

(59). (If removed at disassembly).

(2)

Press the front bearing cone (60) tight against the

shaft shoulder and then install the washer (61) and

locknut (62). Torque the locknut to 300 ft-lb (406.80

N.m).

(3)

Coat the splined bore of the gear (38) with

Lubriplate (Appendix D, Item 34).

(4)

Lower the rear output gear (38) into the case with

the flat face against the back wall of the case and

the chamfered side toward the front of the case.

(5)

Coat the shaft splines with Lubriplate (Appendix D,

Item 34).

(6)

Insert the shaft through the proper hole in the front

of the case and align the shaft splines with the gear

splines. Protect the threaded end of the shaft and

tap the shaft into the gear until the retaining ring

seats in the chamfer of the gear.

(7)

Install the spacer ring (39).

Use heat-resistant gloves when working with high

temperatures.

(8) eat the rear bearing cone (40) to approximately 250°

(121° C). Handle bearing with heat resistant gloves

and install quickly after heating, tapping it into place

if necessary.

(9) Install the spacer tube (63) onto the shaft (59).

(10) Move the shaft toward the front of the case to

visually inspect the mating parts.

(11) Install the front bearing cup (37) and the rear

bearing cup (64) allowing the rear cup to remain

projecting between 3/8 inch and1/4 inch from the

case.

(12) Install the rear output carrier gasket (65) and the

rear output carrier (36) along with seal (66). Coat

retaining bolt threads in sealant (Appendix D, Item

47), install and torque bolts (67) to 45 ft-lb (61.02

N.m).

6-100

|