|

| |

TM5-4210-229-14&P

6-16.

REAR RETAINER OIL SEAL REPLACEMENT.

This task covers:

a. Removal

b, Installation

INITIAL SET-UP

Tools

General Mechanics Tool Kit

Equipment Condition

Para.

Condition Description

Materials/Parts

6-13

Flywheel Removed

Rear Seal Kit (691631C91)

Oil (Appendix D, Item 37)

Grease (Appendix D, Item 21)

RTV Sealant (Appendix D, Item 45)

REMOVAL

a.

Using a chisel, split the oil seal.

Be careful not to damage the seal bore in the

housing.

b.

Remove the seal from the flywheel housing.

c.

Cut the wear sleeve with a muffler chisel. Be

careful not to damage the crankshaft flange.

d.

Remove the wear sleeve.

INSTALLATION

Care should be taken not to damage the bore

while filing the chamfer edge.

a.

Inspect the oil seal bore for a chamfer. If no

chamfer is found, use a file to break the edge of

the bore. This will prevent possible damage to

the oil seal casing during installation.

b.

Prior to wear sleeve and oil seal installation,

clean the bore and crankshaft of all foreign

material.

c.

If the oil seal and wear sleeve are not utilized

(reassembled), assemble seal to sleeve prior to

installing onto crankshaft.

(1) Clean and lubricate single lip seal with clean oil

(Appendix

D,

Item

37).

(2) Fill double lip seal with grease (Appendix D,

Item 21) at cavity between lips.

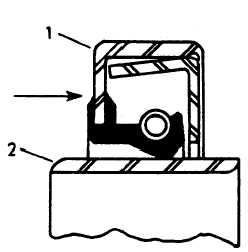

Seal (1) must be installed onto side of sleeve

with chamfer in O. D. (2) to avoid damage to

seal lip.

(3)

Assemble seal (1) onto sleeve by pushing the

seal in the direction of the arrow.

NOTE

Seal bore in housing must be concentric with

crankshaft within 0.010 inch (0.25 mm) full

indictor measure as shaft is rotated 360°.

6-93

|