|

| |

TM5-4210-229-14&P

6-15

TRANSMISSION REPAIR (Continued)

(4) Install ten of the twelve 3/8-16x3-3/8 inch

bolts and rubber-covered washers. Remove

the two guide bolts and install the two

remaining support bolts. Do not tighten the

bolts in sequence. Maintain an even pull on

the outer perimeter of the support by

tightening the first two bolts 180 degrees

apart

to

15

ft-lb

(20

N.m).

Move

approximately90 degrees around the bolt

circle and re-peat the operation. Torque the

remaining opposite pairs of bolts. Repeat the

entire process, tightening all twelve bolts

to24-32 ft-lb (33-43 N.m).

c.

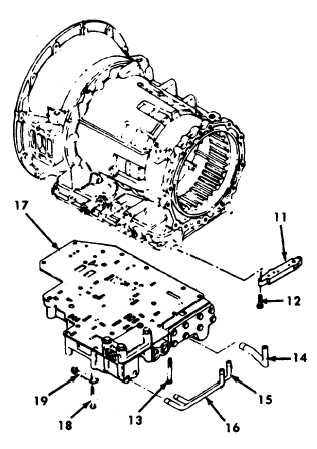

Control valve installation.

With the range selector valve suitably

secured, position the control valve assembly

so the actuator pin enters the housing bore.

Install the control valve body (17) and retain it

with two 1/4-20x3 inch bolts and seventeen

1/4-20x2-1/4 inch bolts. Do not install the two

first clutch feed tube retainer bolts (1 3).

Leave the bolts sufficiently loose to move the

valve body for engagement of the selector

valve with the shift pin.

d.

Tube adapter installation.

(1) Place the tube adapter (11) and tubes

(14)and (15) in position so the tubes can be

inserted into their respective bores in the

valve body.

(2) Install the long first clutch feed tube (14)into

the drilled boss on the valve body. Insert the

governor feed and pressure tubes(15). Be

sure each tube is seated properly.

(3) Install four 1/4-20x1-1/4 inch bolts (12) to

retain the tube adapter (11). Torque the bolts

to 8-12 ft-lb (11-16 N.m)

(4)

Engage the notch in the range selector valve

with the pin on the detent lever. Position the

detent spring (1 9) to engage a notch in the

detent lever and install one 1/4-20x1 -3/4

inch bolt (18) to retain it. Install the two bolts

(13) that retain the first clutch feed tube (14).

Torque the bolt to 8-12 ft-lb (11-16 N.m).

Working from the center outward, torque two

1/4-20x3 inch bolts and seven-teen

1/4-20x2-1/4 inch bolts to 8-12 ft-lb (11-16

N.m).

(1)

e. Valve body installation.

Install

the

modulated

lockup

valve

body

assembly (10). Install three 1/4-20x2 inch bolts

to retain the valve body. Torque the bolts to

8-12ft-lb (11-16 N.m).

f.

Oil filter and pan installation.

When installing the oil filter (7), oil filter tube(8), and

sealring (9), care must be exercised to prevent

twisting the tube or filter in any way that might pinch,

cut or deform the sealring. An air-tight seal must be

maintained to enable the oil pump to draw oil from

the sump free of entrained air.

6-90

|