|

| |

TM5-4210-229-14&P

6.15

TRANSMISSION REPAIR (Continued)

(c)

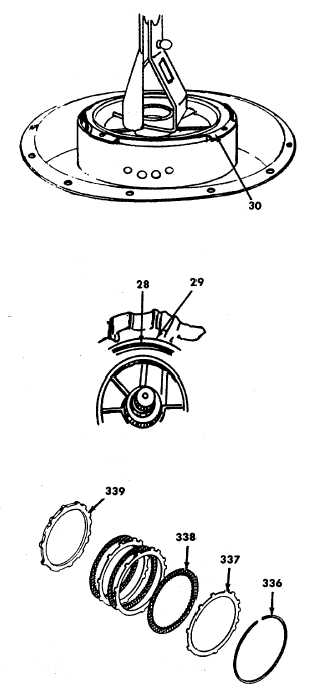

Align the tapped hole in the support with the

anchor bolt hole in the transmission housing.

Install the center sup-port (30) and seat it firmly

against the second clutch snapring.

(d)

Remove the lifter from the center sup-port. Start

a new 3/8-16x3 inch special selflocking bolt and

chamfered washer into the center support

assembly.

(e)

Install the snapring (29) to retain the center

support (28). Place the snapring gaps at the top

of the main case. Torque the center support

anchor bolt to 39-46 ft-lb (53-62 N.m).

Improper installation of butt-joint sealrings may

cause transmission failure.

(f)

Install

needle

roller

thrust

bearing

race

assembly, lube relief scallops, black oxide race

up, onto the center support hub. Install two

sealrings onto the hub.

(8) Third clutch clearance.

(a)

Starting with an external-tanged plate(337),

alternately install the three external-tanged

plates (337) and three internal-splined plates

(338). Note location of the three set of double

tangs. If the tangs are not positioned properly,

movement of the stationary plates will occur.

(b) Install the backplate (339) and retain it with the

snapring (336). Using third clutch clearance

gauge, check the clearance between the

snapring (336) and

backplate (339). The

prescribed clearance for the third clutch is 0.050

to 0.114inch (1.27 to 2.90mm). When this

clearance is achieved, the first step of the gauge

will fit between the snapring and the backplate;

the second step will not.

(c) If the clearance is not satisfactory, measure the

total plate thickness and replace all plates

necessary to satisfy the prescribed clearance. If

required, the backplate (339) may be replaced by

a thicker or thinner plate.

(d)

6-88

|