|

| |

TM5-4210-229-14&P

6.15

TRANSMISSION REPAIR (Continued)

NOTE

All replacement parts orders require information from

the nameplate. Therefore it is imperative that the new

nameplate (331 ) (if replaced)be stamped with

identical information.

(h) Remove the drive screw (330) and nameplate

(331) only if its replacement is necessary.

(2) Assembly.

(a) If the 1/8 inch plugs (328) and (329)were

removed, replace them. Torque the plugs to 4-8

ft-lb (5-11 N.m). If anew nameplate (331) is

required, all information on the old plate must be

metal stamped into the new plate. In-stall the

new plate (331) and retain it with a drive screw

(330).

(b) If lubrication valve (323), spring (324)and tube

(325) were removed, install new parts. Assemble

valve (323) and spring (324) onto tube (325),

respectively. Install the assembly (327) into its

bore in housing (326). Press the valve tube (325)

into its bore until it is 0.58 inch (14.7 mm) below

the external surface of the adapter mounting

boss. Utilization of lube valve spring guide tool

simplifies the installation of the lube valve

assembly (327). Install a new gasket (322) onto

the valve adapter (321). Install the adapter into

the bore. Retain the adapter (321) with two new

1/4-20x7/8 inch socket-head bolts (320). Use

bolts (320) only one time. Torque the bolts to

12-15 ft-lb (16-20N.m).

(c) If plug (317) and washer (318) or the two 1/8 inch

plugs (319) were removed, replace them. Torque

the 3/4-16 plug (317) to 50-60 ft-lb (68-81 N.m).

Torque the two 1/8 inch plugs (319) to4-8 ft-lb

(5-11 N.m).

(d) Place the selector shaft oil seal (311)

sealing lip away from tool onto selector

shaft seal installer. Install the seal(311) into

the housing bore. Lubricate the inner bore of

the seal. Selector shaft seal installer permits

installation of the oil seal with or without the

selector shaft (315) installed.

(e) Guide the grooved end of selector shaft

(315) through seal (311) after removing

burrs from the shaft to protect the oil seal.

Position detent lever (312) so that the

selector valve pin extends toward the inside

of the housing, and engage the slot in the

detent lever with flats on the selector shaft.

Install nut (314) and retainer pin (313) to

retain the shaft and lever. Torque the nut

(314) to 15-20 ft-lb (20-27 N.m)

(f) If the breather (316) was removed, in-stall a

new

breather.

Tighten

the

breather

sufficiently, using care not to distort or crush

the breather stem.

ASSEMBLY

a.

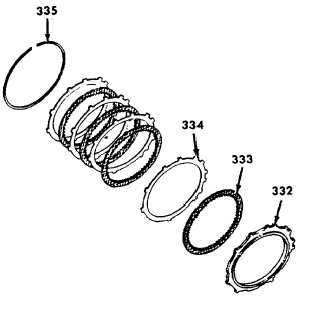

Clutches, center support, planetary gearing and

rear cover assembly.

(1)

Selecting center support snapring.

(a) Position the transmission housing, converter

end up. Install second clutch backplace

(332).

6-83

|