|

| |

TM5-4210-229-14&P

6-15.

TRANSMISSION REPAIR (Continued).

clearance is still excessive after all eight

plates and the backplate have been

replaced, a thicker piston (229) is required.

(g) If the clearance is insufficient (first step of

gauge will not fit), a thinner piston (229) is

required.

(h) Install the piston return spring (224) and

spring retainer (222). Using compressor

tool and compressor base, depress the

spring retainer (222). Install the snapring

(223) to retain the spring retainer (222).

(i) Install the bearing race (221) outer lip first,

onto the rear hub of the clutch housing.

Use oil-soluble grease (Appendix D, Item

21) to retain the races during subsequent

assembly.

g. Center support assembly repair.

(1) Disassembly.

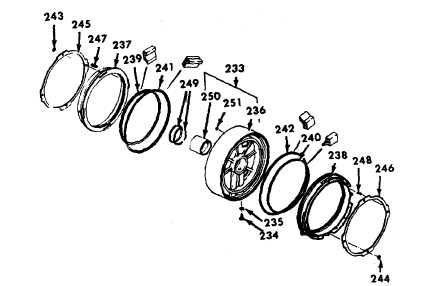

(a) Place center support assembly (233)

vertically (upright), on the work table.

(e) If

parts

replacement

is

necessary,

disassemble the two piston assemblies.

Cut the self-locking retainer rings (243 and

244) to prevent damaging the piston

projections, Remove four self locking

retainer rings (243 and 244), a retainer

(245 or 246) and twenty springs (247 or

248) from each piston (237 or 238).

(f) Remove two sealrings (249) from the hub

of the center support assembly.

(g) If the bushing (250) in the center support is

worn or damaged, collapse the bushing

(250) inward at the bushings splitline and

remove.

(h) Remove the ball (25 1) freed by removing

the bushing (250) from the hub of the

support (236).

(i) Determine the serviceability of the sealring

grooves on the center support hub. Insert,

do not force, gauge into the groove on the

center support hub. Rotate the gauge 360

degrees around the hub. If the gauge does

not rotate freely, the support is damaged

and should be replaced.

(b) Remove oil filter (234) and sealring (235)

from center support (236).

(c) Remove pistons (237 and 238) with

attached parts.

(d) Remove the inner sealrings (239 and 240)

and outer sealrings (241 and 242) from

each piston.

6-71

|