|

| |

TM5-4210-229-14&P

6-15.

TRANSMISSION REPAIR (Continued).

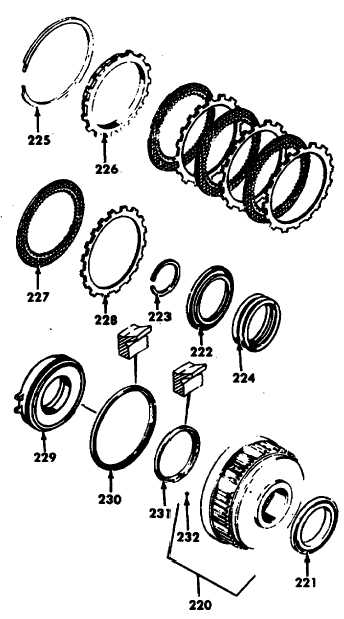

(c) Remove the eight clutch plates (227 and

228) and piston (229). Remove sealring

(230) from the piston and sealring (231)

from fourth clutch housing (220).

(d) Remove balls (232) from fourth clutch

housing (220) only if replacement is

necessary. If necessary, clear the affected

bores of staked metal and remove the

balls (232).

(2) Assembly.

(a) If balls (232) were removed, replace them.

Place each ball in its bore. Stake each

bore at three equally spaced places. Each

bore is properly staked when the ball has

at least 0.040 inch (1.02 mm) axial

movement and when the ball is retained by

the stakes when a 301b (133 N) load is

applied against the ball.

(b) Before completing the assembly, the clutch

clearance

must

be

established.

One

method is by direct measurement and is

outlined in (c) through (g).

CAUTION

If either piston sealring (230 or 231) is

installed incorrectly, the fourth clutch

will not operate properly.

(c) Position the fourth clutch housing, rear hub

downward, on a work table. Lubricate and

install the piston sealrings (230 and 231)

into their grooves in the housing hub and

piston. Make sure the sealring lips face

toward the oil pressure side of the piston.

(d) Install the piston (229) into the fourth clutch

housing.

Alternately

install

the

four

external-tanged plates (228) and four

internal-splined plates (227). Install the

backplate (226) and retain it with the

snaprings (225).

(e) Using fourth clutch clearance gauge, check

the clearance between the backplate and

the

first

internal-splined

plate.

The

prescribed clearance for the fourch clutch

is 0.064-0.125 inch (1.625-3.175 mm).

When this clearance is achieved, the first

step of the gauge will fit between the

backplate (226) and the clutch plate; the

second step will not.

(f) If the clearance is excessive (second step

of gauge fits), replace the thinner clutch

plates with new plates. If the

6-70

|