|

| |

TM5-4210-229-14&P

6-6. CYLINDER HEAD AND VALVES MAINTENANCE (Continued).

u. Lubricate bolt threads, bolt head seating areas

and washers with clean lubricating oil (Appen-

dix D, Item 36).

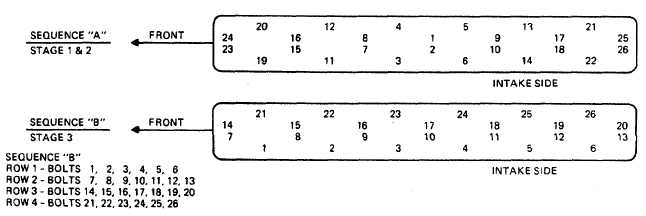

v. Torque bolts in three stages:

Stage 1: Following sequence "A" torque bolts

to 110 ft-lb (150 N.m).

Stage 2: Following sequence "A" torque bolts

to 155 ft-lb (210 N.m).

Stage 3: Following sequence "B" torque bolts in

rows, 165 ft-lb (225 N.m).

CAUTION

Do not back bolt off, pull up to torque level

indicated. Check the two end rocker arms

for freedom of motion after torquing first

stage.

Do not adjust valves with the engine

running. Severe damage can result from

inserting feeler gauge between valve and

valve lever due to close clearance of valve

piston.

w. Valve lash adjustment.

NOTE

Valve lash may be adjusted as a separate

operation without cylinder head and valve

lever removal, disassembly, cleaning, inspec-

tion or repair.

All valves are adjusted by cranking the engine

only twice.

Perform valve lash adjustment with the engine

warm which means any temperature above

freezing.

(1) Turn the crankshaft until the number one

piston is on the compression stroke and the

timing pointer on the front cover is in line

with the top dead center mark (pin) on vib-

ration damper or flywheel.

NOTE

Be sure that the number one piston is on the

compression stroke by turning both push rods

by hand to determine that both valves are

closed. Valves are closed when push rods are

loose and can be turned easily.

(2) Six valves are adjusted when the number 1

piston is at top dead center (compression)

and the remaining six are adjusted when the

number 6 piston is at top dead center (com-

pression). Odd numbered valves are intake

valves; and even numbered valves are ex-

haust valves.

(3) Valve tappet clearance (lash) is 0.025 inch

(0.64 mm) for intake valves and exhaust

valves.

CAUTION

When tightening head bolts, place a 0.005 inch

(0.127 mm) feeler gauge between the outside

brackets and the rocker levers to prevent

binding.

6-13

|