|

| |

TM 5-4210-229-14&P

6-6.

CYLINDER HEAD AND VALVES MAINTENANCE (Continued)

l.

Return each valve (and its parts) to the position

from which it was removed.

m.

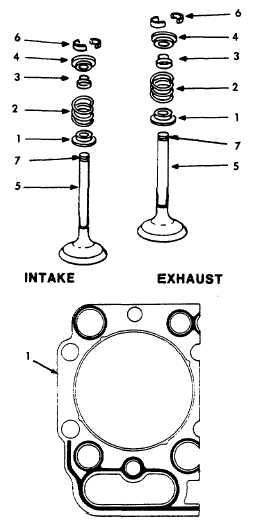

Place valve seat (1), spring (2), oil shield (3),

and rotator (4) onto stem of valve (5).

n.

With a valve spring compressor, compress the

spring (2) far enough to install the valve locks (6)

into the keeper groove (7).

Cleaning solvent (Appendix D, Item 54) is

both toxic and flammable. Keep off skin.

Use only in a well-ventilated area and avoid

prolonged breathing of vapors. Keep away

from open flames.

Compressed air used for cleaning or drying

can create airborne particles that may enter

the eyes. Pressure shall not exceed 30 psi

(206 kPa). Wearing of goggles is required to

avoid injury to personnel.

o.

Clean and dry cylinder head gasket surfaces with

solvent and compressed air.

p.

Blow

out

cylinder

head

bolt

holes

with

compressed air to prevent hydrostatic lock and

possible block cracking when bolts are torqued.

Do not use gasket cement. Heat transfer

may be adversely affected.

q.

Install new cylinder head gasket (1).

r.

Install rocker arm, shaft, and push rods on

cylinder bead (paragraph 6-5).

When lifting an object, make sure the hoist and

sling are fastened securely. Be sure the item

being lifted does not exceed the capacity of the

lifting device.

s.

Use a hoist and sling to place and align head on

crankcase dowels. Maintain gasket alignment.

t.

Using an accurate torque wrench, torque cylinder

head bolts in three stages.

6-12

|