|

| |

TM5-4210-229-14&P

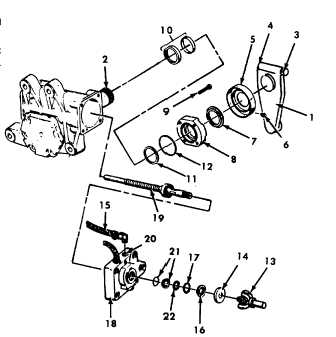

5-23. POWER STEERING GEAR REPAIR (Continued).

e.

Position catch basin beneath gear to protect

against fluid spill during removal of trunnion cover

(8).

f.

Remove four trunnion cover bolts (9) and trun-

nion cover (8).

g.

Remove two-piece sector shaft seal (10), teflon

backup washer (11) and trunnion cover sealring

(12).

Cleaning solvent (Appendix D, Item 54) is both

toxic and flammable. Keep off skin. Use only in

a well-ventilated area and avoid prolonged

breathing of vapors. Keep away from open

flames.

h.

Clean trunnion cover (8) with solvent (Appendix

D, Item 54).

i.

Mark to assure proper alignment during as-

sembly remove input coupling (13) and seal

protector (14). If coupling (13) is tight, insert

screwdriver into slot to release.

j.

Clean the area around the input shaft using fine

emery paper (Appendix D, Item 13).

k.

Remove and plug the return line (15).

l.

Remove and discard seal (16) and remove seal

retaining ring (17) from the valve housing (18).

Compressed air used for cleaning or drying can

create airborne particles that may enter the eyes.

Pressure shall not exceed 30 psi (206 kPa).

Wearing of goggles is required to avoid injury to

personnel.

m.

Hold a piece of cloth (Appendix D, Item 14) over

the worm shaft/input shaft (19) and apply air pressure to

the valve housing return port (20). This will force the

two piece input shaft seal (21) and steel backup washer

(22) to pop out of the gear. Discard the two piece seal.

REPAIR

Repair consists of replacing damaged or defec-

tive components.

ASSEMBLY

a.

Apply grease (Appendix D, Item 22) to the new

input shaft seal (21) and steel backup washer (22)

and to the input shaft (19).

b.

Install the two piece seal (21) flat side up and the

steel backup washer (22) using seal driver.

c.

Install retaining ring (17).

d.

Pack the area around the input shaft with high

temperature grease (Appendix D, Item 22).

e.

Install the new seal (16) using the seal driver.

f.

Add more grease (Appendix D, Item 22) and

assemble seal protector (14) onto worm shaft/

input shaft (19) seating it in the relief groove just

beyond the input shaft serrations with cup side

toward the gear.

g.

Remove plug in return line (15) and reconnect the

return line to the steering gear.

h.

Reconnect input coupling (13) aligning marks

properly.

5-55

|