|

| |

TM5-4210-229-14&P

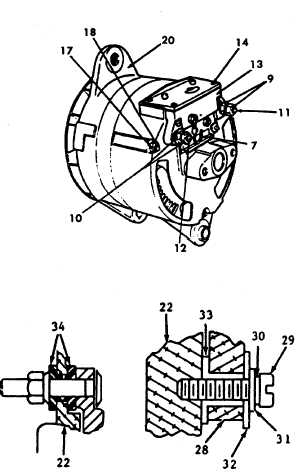

5-12.

ALTERNATOR REPAIR (Continued).

n.

Using a bearing puller remove drive end housing

(20) and bearing assembly (35) from the rotor shaft

(19).

o.

Remove four screws (36) and bearing retainer (37)

and press bearing out of drive end housing.

p.

With a heat gun, remove wire (38) that connects the

rotor coil (19) to the outside slip ring (39). Unsolder

the wire from the inside slip ring (40) and with a

bearing puller, remove the slip ring assembly and

insulation washer (41).

q.

Using a bearing puller, remove the bearing (42).

TEST

NOTE

Before performing these tests, inspect all parts

for wear, cracks, or other mechanical defects.

Replace all damaged parts.

a.

Positive heat sink test.

NOTE

The positive heat sink is the one to which

positive output terminal is connected. The

square hole in the positive heat sink is larger

than the negative heat sink hole.

(1)

Connect the positive lead of the test lamp to

the positive heat sink and touch the negative

test lead to each of the three diode terminals.

The test lamp should not light. If the test

lamp lights, the diode is shorted.

(2)

Reverse the test leads so that the negative

test lead is connected to the positive heat

sink. The positive test lead should now be

touched to each diode terminal. If the test

lamp fails to light, an open diode is indicated.

(3)

If a shortened or open diode is detected,

replace the entire heat sink assembly.

b.

Negative heat sink test.

(1)

Connect the negative lead of the test lamp to

the negative heat sink and touch the positive

test lead to each of the three diode terminals.

The test lamp should not light. If the test lamp

lights, the diode is shorted.

(2)

Reverse the test leads so that the positive test

lead is connected to the negative heat sink.

The negative test lead should now be touched

to each diode terminal. If the test lamp fails to

light, an open diode is indicated.

(3)

If a shorted or open diode is detected, replace

the entire heat sink assembly.

5-29

|