|

| |

TM5-4210-229-14&P

4-182. PITMAN SHAFT SEALREPLACEMENT.

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Tools

General Mechanics Tool Kit

Drift

Materials/Parts

Power Steering Fluid (Appendix D, Item 19)

Seal Kit (As Required, Appendix E, Figure E-136)

Crocus Cloth (Appendix D, Item 12)

Solvent (Appendix D, Item 54)

Grease (Appendix D, Item 22)

Equipment Condition

Para. Condition Description

4-176 Pitman Arm Removed

General Safety Instructions

Engine OFF.

Transmission in (N) neutral.

Parking brake set.

REMOVAL

a.

Position a drain pan under the steering gear.

b.

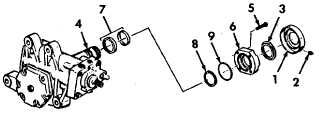

Remove protector boot (1), grease fitting (2) and

dirt and water seal (3). Discard protector boot and

dirt and water seal.

c.

Clean the sector shaft (4) with a crocus cloth

(Appendix D, Item 12). Be sure to remove any

paint.

d.

Remove the four trunnion cover bolts (5) and

trunnion cover (6). Then remove and discard the

sector shaft seal package consisting of the

two-piece sector shaft seal (7), the Teflon back-up

washer (8) and the trunnion cover seal ring

(9).

Cleaning solvent (Appendix D, Item 54) is both toxic

and flammable. Keep off skin. Use only in a

well-ventilated area and avoid prolonged breathing of

vapors. Keep away from open flames.

e.

Clean the trunnion cover (6) with solvent

(Appendix D, Item 54) and inspect the seal cavity

and sealing face for nicks or corrosion. Replace the

trunnion cover (6) with a new one if these

conditions exist.

INSTALLATION

a.

Place the trunnion cover (6) on a bench to install

the new seal package. Start with the Teflon backup washer

(8).

The words OIL SIDE must be visible on the seal after it

is in place. The seal will not function if the seal is

reversed and a loss of power steering assist may

occur.

b.

Install the two-piece sector shaft seal (7) so that the

words OIL SIDE are visible after seal is in place.

c.

Grease the new trunnion cover seal ring (9) and

install it into the cover groove.

d.

Cover the serrations of the sector shaft (4) with only

one layer of tape to avoid damaging the seals

during installation.

e.

Install the trunnion cover (6) and four trunnion bolts

(5). Torque bolts to 15-22 ft-lb (20- 30 N.m) if dry or

11-16 ft-lb (15-22 N.m) if lubricated.

f.

Pack clean high temperature grease (Appendix D,

Item 22) around seal area of sector shaft (4). Install

a new dirt and water seal (3) using a suitable blunt

end drift.

g.

Apply a generous amount of the same grease

(Appendix D, Item 22) to the protector boot (1) in the

area inside of the small diameter ring. Assemble

protector boot onto sector shaft (4) and trunnion

cover (6) locating the grease fitting hole toward the

input shaft end of gear assembly. Insert grease

fitting (2) into protector boot. Remove tape from

sector shaft serrations.

h.

Install the pitman arm (paragraph 4-176).

i.

Fill the steering fluid system (Appendix D, Item 19)

(paragraph 4-180) and bleed system as needed.

4-197

|