|

| |

TM5-4210-229-14&P

4-163. TIRE REPLACEMENT (Continued).

NOTE

Recommended vehicle tire mounting and

inflation procedures are especially important

with radial tires. Failure to follow these

procedures can cause bead deformation due to

incorrect bead seating. Bead deformation may

lead to chafing, lower sidewall and bead area

packing, eccentric wear, ride vibratin and

non-retreadable castings.

d. Install valve core and inflate to proper pressure.

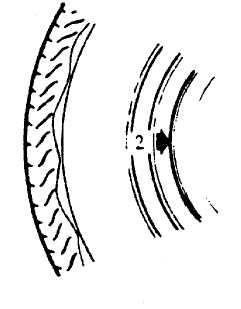

Check the locating rings (2) of the tire to be sure

they show around the rim flanges on both sides.

e. Check the spacing between the rim flange and one

of the three lower sidewall rim line rings while the

tire

is

laying

flat

to

verify

bead

seating.

Measurements must be taken each 90 degrees

around the circumference of the rim flange.

NOTE

If the spacing is uneven around the bead from

side to side, repeat steps a through c, then

recheck.

Before re-installing the rims, remove any build

up of corrosion on the rim mounting surface

and disc mounting surface by scraping and

wire brushing. Installing rims without good

metal-to-metal

contact

at

the

mounting

surfaces can cause lug nuts to loosen. This

can lead to a rim coming off while the vehicle is

moving, causing loss of control.

f. Place the tire rim assembly in position on the hub

and install the lug nuts snugly in a criss-cross

pattern to minimize runout.

NOTE

Lateral runout should not exceed 0.125 inch

(3.18 mm) on the front wheels and 0.187 inch

(4.76 mm) on the rear wheels.

g. Turn the wheel until one nut is at the top of the bolt

circle, then tighten evenly and alternately according

to a torque of 190-210 ft-lb (258-285 N.m).

h. Inflate tire(s) to 80 psi (551.6 kPa).

i. Lower vehicle.

4-179

|