|

| |

TM5-4210-229-14&P

4-76. FUEL INJECTION PUMP REPLACEMENT (Continued).

REMOVAL

a.

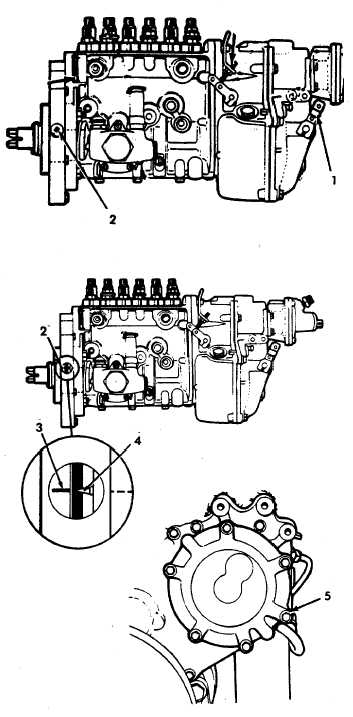

Disconnect accelerator cable or linkage from outer

injection pump control lever (1).

b.

Remove injection pump timing pointer plug (2) and

gasket from left side of pump mounting adapter.

c.

Rotate engine in normal operating direction until

engine front cover timing pointer is approximately

90 degrees from top dead center dot on crankshaft

pulley. (The injection pump is driven at one-half

engine speed. Therefore, each time the injection

pump hub mark (3) is aligned with injection pump

timing pointer (4), engine should be on number one

cylinder compression stroke.

d.

Turn engine slowly in normal direction of rotation

until timing mark (3) on hub is aligned with injec-

tion pump timing pointer (4) (observe through

mounting adapter timing plug hole (2)). If engine is

turned past timing mark, rotate engine counter-

clockwise at least 90 degrees to remove gear train

backlash. Rotate engine until timing mark (3) and

pump timing pointer (4) are aligned.

e.

Observe engine front cover timing pointer and

crankshaft pulley degree alignment. To ensure an

accurate reading, view pointer straight on the en-

gine should now be positioned at specified static

pump to engine timing. If timing is not within speci-

fications, rotate engine to correct crankshaft posi-

tion (specified degrees before top dead center)

before removing injection pump. If necessary to

rotate engine in opposite direction of normal rota-

tion to achieve specified timing, rotate engine to 90

degrees before top dead center and then rotate

engine to specified timing. This procedure takes up

gear backlash.

f.

Remove high pressure injection lines as an as-

sembly of six lines from injection nozzles and

pump. Cap all openings to keep dirt out of fuel

system.

g.

Remove or disconnect all other necessary lines,

hoses, and wires from pump.

h.

Cap all openings to keep dirt out of fuel system.

i.

Remove injection pump drive gear access cover

capscrews and washers (5).

4-88

|