|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-224-14&P

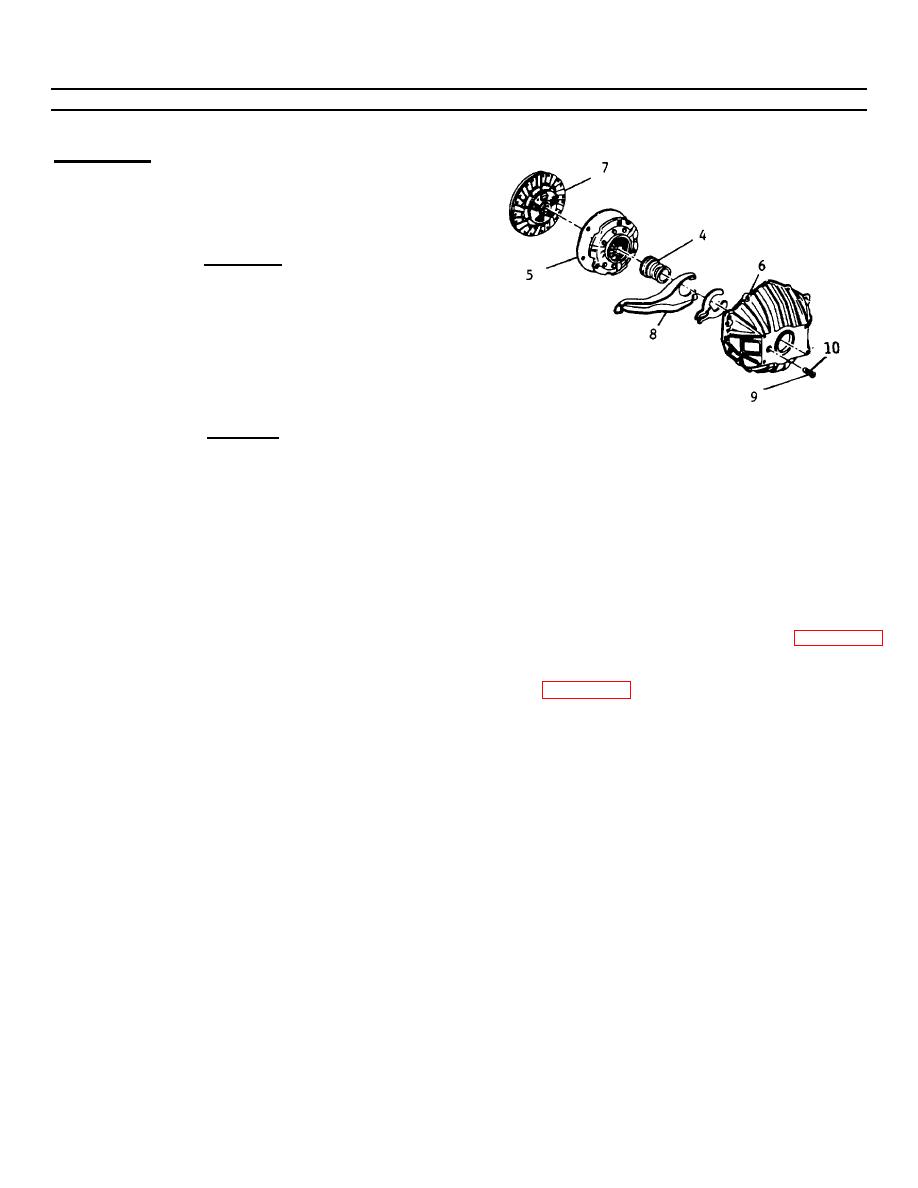

6-22. CLUTCH ASSEMBLY REPAIR. (Continued)

INSPECTION

a. Check drive straps for looseness at the clutch

cover and evidence of looseness at pressure

plate bolt holes.

WARNING

Cleaning

solvent,

Federal

Specification P-D-680, is both toxic

and flammable.

Keep off skin.

Use only in a well ventilated area

and avoid prolonged breathing of

vapors.

Keep away from open

flame.

NOTE

CAUTION

Ball spring (10) on fork (8) may be

The release bearing (4) is

bent in toward fork if necessary.

permanently packed with lubricant

and should not be soaked in

g.

Inspect clutch fork ball socket and fingers for

cleaning solvent as this will

wear and ball retaining spring (10) for damage.

dissolve the lubricant.

Spring should hold fork tightly to ball stud (9).

b. Wash all parts, except driven disk and release

bearing, in cleaning solvent.

h. Inspect ball stud (9) for wear. Replace if scored.

i. Check run out of transmission pilot hole in clutch

c. Inspect pressure plate (5) and flywheel housing

housing by removing a flywheel bolt and

(6) for scores on the contact surfaces. Use a

installing a dial indicator.

straight edge and check for flatness of contact

j. Lubricate ball stud (9) with lubricant (Appendix D,

surfaces.

Item 23) before reassembly.

d. Check release bearing (4) for roughness and

k. Lubricate bearing I.D. and groove with lubricant

freedom of movement on the sleeve of the

transmission clutch gear bearing retainer.

Replace retainer if rough.

e. Inspect clutch disc (7) for worn, loose or oil

soaked facings, broken springs, loose rivets,

etc. Replace if necessary.

f. Examine splines in hub and make sure they slide

freely on splines of transmission clutch shaft. If

splines are worn, the clutch disc or clutch gear

should

be

replaced

as

necessary.

6-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |