|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-4210-224-14& P

6-8.

CYLINDER HEAD MAINTENANCE. (Continued)

INSPECTION

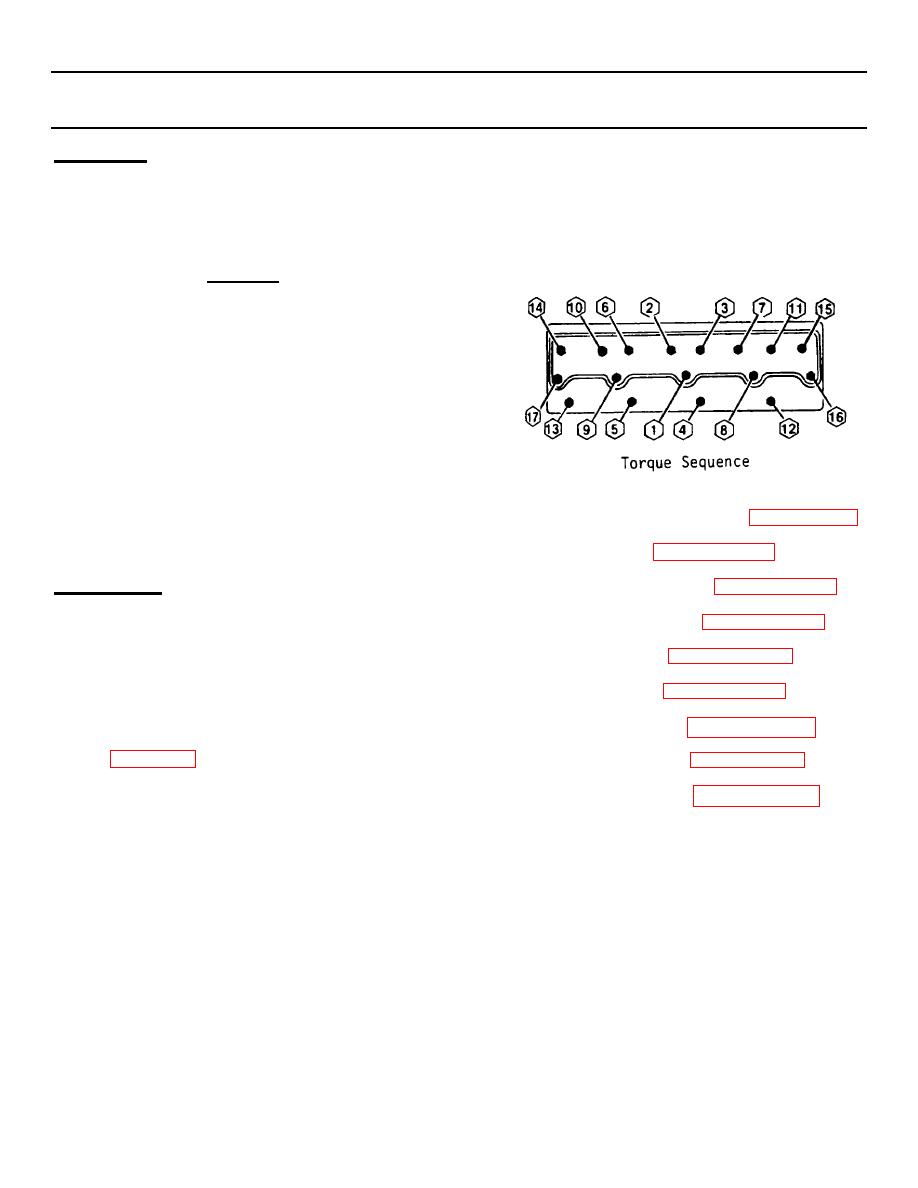

e. In sequence, torque cylinder bolts to 50 ft-lbs

(65 N-m).

Inspect the cylinder head for cracks in the exhaust

ports, combustion chambers, and for external

f. In sequence, torque all bolts an additional 900

cracks to the coolant chamber or any other

degrees (1/4 turn).

damage.

CAUTION

Measure the cylinder head. If warped

more than 0.006 inch (0.15 mm)

longitudinally or 0.003 inch (0.08 mm)

transversely, replace the cylinder head.

All gasket surfaces must be entirely

free of dirt, sand and foreign matter

directly before and during assembly.

Head gaskets are a special composition

gasket that must be used without a

sealer.

g. Install rocker arm assemblies (paragraph 6-5).

Left rear cylinder head bolt must be

installed into head prior to installation

h. Install dip stick (paragraph 4-113).

INSTALLATION

i. Install rocker arm cover (paragraph 4-112).

a. Place the head gasket on the engine block over

j. Install intake manifold (paragraph 4-110).

the dowel pins.

k. Install glow plugs (paragraph 4-108).

b. Carefully guide the cylinder head into place over

the dowel pins.

l. Install alternator (paragraph 4-107).

c. Coat threads and underside of cylinder head

m. Install exhaust pipes (paragraph 4101).

bolts with sealant and install bolts finger tight

n. Install injection lines (paragraph 4-92).

d. Torque the cylinder head bolts in sequence

o. Install cooling system (paragraph 472).

shown to 20 ft-lbs (25 N-m).

6-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |