|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-4210-224-14&P

5-10.

STARTER REPAIR. (Continued)

motor, the connector strap terminals must

terminal. Adjust the voltage to 10 volts

be removed from the terminal on the

and note the ammeter reading. It should

solenoid before making these tests.

be 41 to 47 amperes for all starting

Complete tests in a minimum of time to

motors.

prevent overheating of the solenoid.

NOTE

Current will decrease as windings heat

up.

(d) Current draw readings that are over

specifications indicate shorted turnes or a

ground in the windings of the solenoid and

the solenoid should be replaced. Current

draw

readings

that

are

under

specifications

indicate

excessive

resistance. No reading indicates an open

circuit. Check connections then replace

solenoid if necessary.

ASSEMBLY

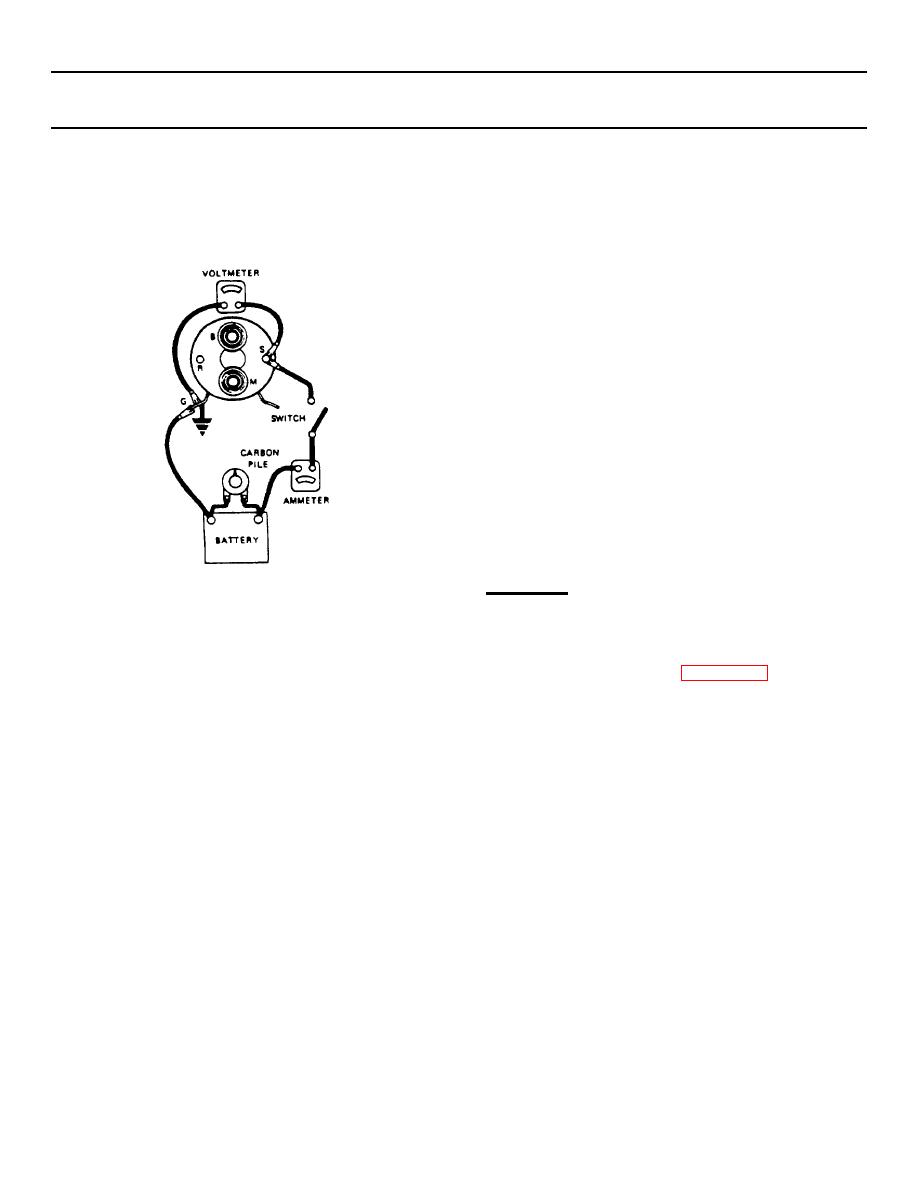

(2) To check hold-in winding, connect an

Assemble the armature and clutch as follows:

ammeter in series with 12-volt battery and

the "switch" terminal on the solenoid.

(1) Lubricate drive end of armature shaft (1)

Connect a voltmeter to the "switch"

with lubricate (Appendix D, Item 17).

terminal and to ground. Connect carbon

pile across battery. Adjust the voltage to

(2) Install center bearing (2) with bearing

10 volts and note the ammeter reading. It

toward the armature winding. Then install

should be 14.5 to 16.5 amperes for all

the fiber washer (3) on the armature shaft

starting motors.

(1).

(3) To check both windings, connect as for

previous test. Ground the solenoid motor

5-24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |