|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-4210-224-14&P

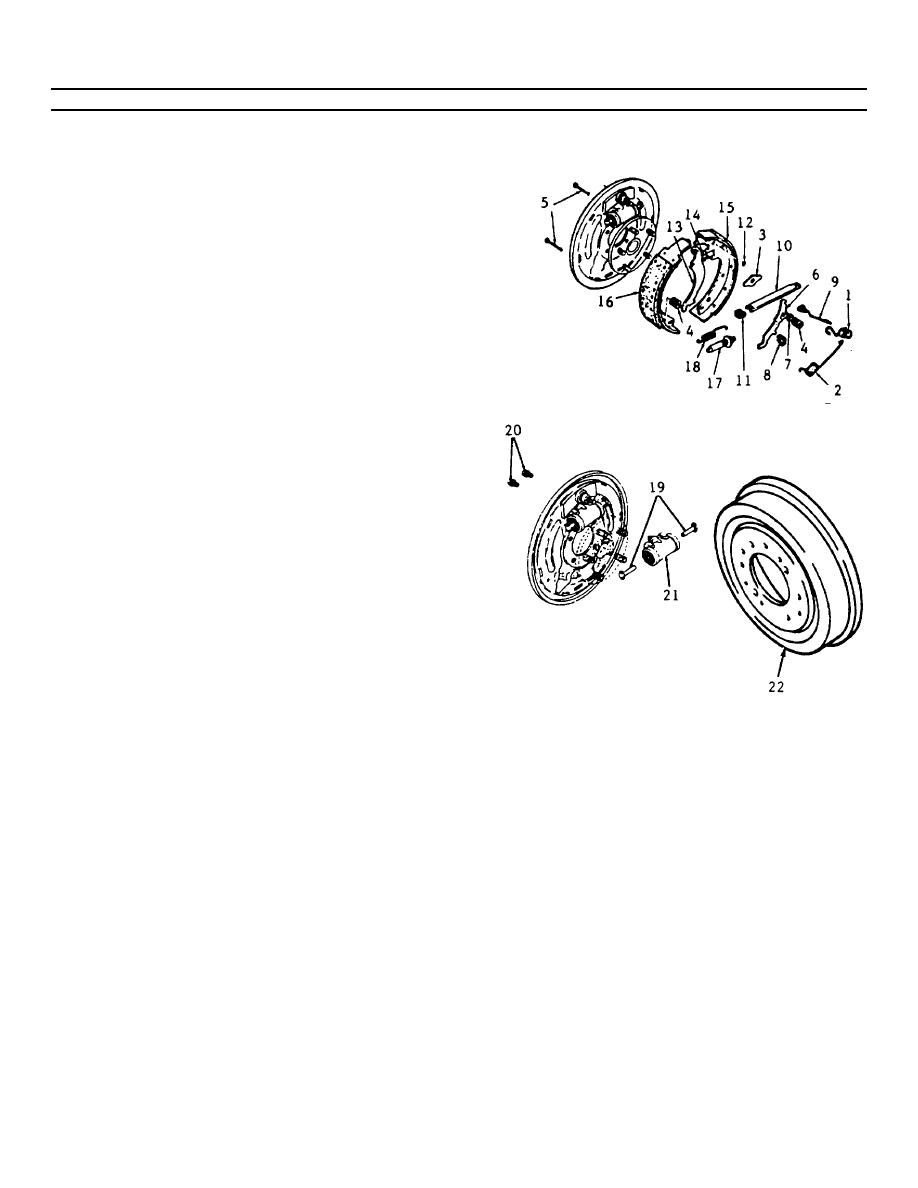

4-219. REAR DRUM BRAKE REPLACEMENT. (Continued)

i. Remove the actuator lever (6) and lever pivot

(7).

j. Remove the lever return spring (8) and actuator

link (9).

k. Remove the parking brake strut (10) and strut

spring (11).

l. Remove the retaining ring (12) parking brake

lever (13) and washer (14).

m. Remove the brake shoes (15 and 16).

CAUTION

Do not interchange the right and

left adjusting screws.

n. Remove the adjusting screw assembly (17) and

adjusting screw spring (18).

o. Remove cylinder links (19) and disconnect inlet

tube line.

p. Remove wheel cylinder bolts (20) and lift off

wheel cylinder (21).

q. Check all parts for signs of wear, discoloration

due to heat, or stress, and replace if necessary.

r. Check the wheel cylinder for signs of leakage.

s. Check the brake drum (22) for scoring and

machining tolerance.

CAUTION

A cracked drum is unsafe for

CAUTION

further service and must be

Machining or grinding of brake

replaced. Do not attempt to weld a

drums

increases

the

inside

cracked drum.

diameter of the drum and changes

the lining-to-drum fit. All brake

drums have a maximum diameter

cast into them. This diameter is

the maximum wear diameter. Do

not machine a brake drum that will

not

meet

the

following

specification.

(1) Smooth up and polish slight scores or

grooves with fine emery cloth.

(2) Machine drums with severe scoring,

pitting, grooves or barrel shaped, bell-

mouthed or out-of-round condition.

4-304

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |