|

|||

|

|

|||

|

Page Title:

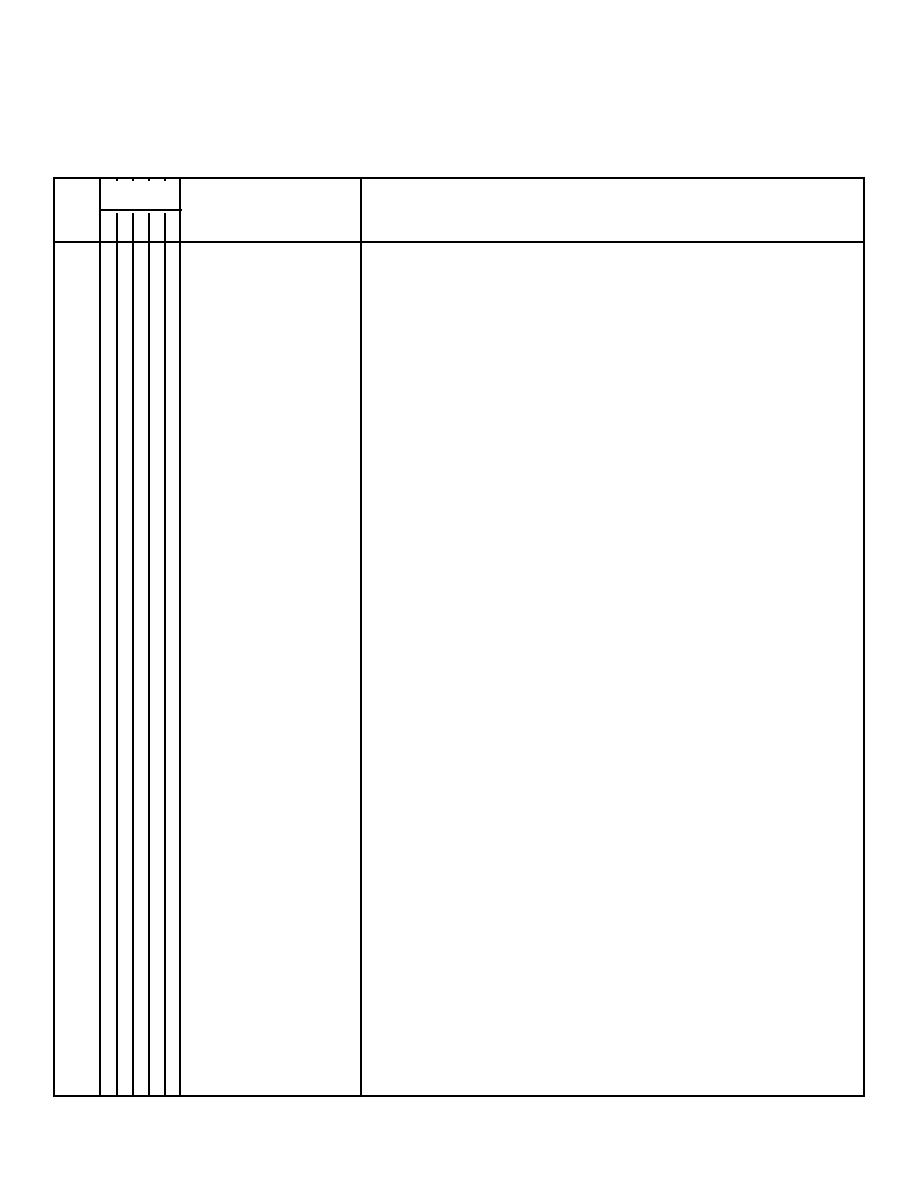

Table 4-2. Organizational Preventative Maintenance Checks and Services (PMCS) - continued |

|

||

| ||||||||||

|

|

TM 5-4210-224-14&P

Table 4-2. Organizational Preventative Maintenance

Checks and Services (PMCS) (Continued)

W - Weekly

Q - QUARTERLY

A - ANNUALLY

M - Monthly

S- SEMI ANNUALLY

INTERVAL

ITEM

ITEM TO BE

NO.

INSPECTED

PROCEDURE

WMQ S A

PROPELLER SHAFT ASSEMBLY

31.

Propeller

Visually inspect propeller shafts for damage, misalignment,

q

Shafts

and unusual noises. Inspect center support bearing,

universal

joints and slip yokes for corrosion, structural damage, and

loose or missing hardware. Lubricate rear propeller shaft,

constant velocity joint, and slip yoke on the front propeller

shaft if unusual noises are evident. If noise(s) continues

replace defective parts. Replace any damage parts that are

found.

TRANSMISSION ASSEMBLY

32.

Transmission

Visually inspect transmission assembly for pitting, scoring,

q

or other structural damage. Check for loose or missing at-

taching hardware.Perform operational check on shift control

lever and linkage. Check transmission fluid level. Add

fluid if necessary. Replace loose or missing hardware.

Replace transmission if defective or damaged. Refer to next

higher level of maintenance for repair.

CLUTCH ASSEMBLY

33.

Clutch

Visually inspect clutch assembly for pitting, scoring. or

q

other structural damage. Check for loose or missing attaching

hardware.Perform operational check on clutch pedal and

linkage. Check clutch reservoir fluid level. Add fluid

if necessary. Replace loose or missing hardware. Replace

clutch if defective or damaged. Refer to next higher level

of maintenance for repair.

TRANSFER CASE ASSEMBLY

34.

Transfer Case

Visually inspect transfer case assembly for pitting, scoring.

q

or other structural damage. Check for loose or missing at-

taching hardware.Perform operational check on transfer case

shift lever and linkage. Check transfer case fluid level.

Add fluid if necessary. Replace loose or missing hardware.

Replace transfer case if defective or damaged. Refer to next

higher level of maintenance for repair.

WHEEL ASSEMBLY

35.

Wheels and Tires

Visually inspect wheel rims for pitting, corrosion, or other

q

structural damage. Inspect wheel rims for loose or missing

lug nuts. Replace any defective or missing parts.

BRAKE SYSTEM

36.

Brake System

Visually inspect brake system for corrosion or other structural

q

damage. Inspect brake lines for damage or leakage. Perform

operational check on brake system. Inspect brake system re-

servoir for proper level. Add silicone fluid if necessary.

Replace any defective or missing parts.

37.

Parking Brake

Perform operational check on parking brake control. Visually

q

Control inspect control linkage for corrosion or structural damage.

Replace or adjust any defective parts.

4-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |