|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

2-12.4

Reducer Gearbox.

This task covers

a. Repair

b. Overhaul

TOOLS

MATERIALS/PARTS

Shop Equipment, Automotive

10, Appendix B Dry Cleaning Solvent

Maintenance and Repair,

13, Appendix B Emery Cloth

NSN 4910-00-754-0705

22, Appendix B Pipe Sealant

29, Appendix B Threadlock Liquid

EQUIPMENT CONDITION

02-23-01262-200 Repair Kit

Reducer Gearbox Removed

(see TM 5-4210-220-12)

NOTE

Keep work area as clean as possible to prevent contamination of components.

REPAIR

NOTE

Reducer gearbox repair consists of replacement of leaking seals and gaskets and shaft end play adjustment.

There are two types of caps on the gearbox, an open cap through which shaft protrudes and a closed cap.

If an open cap is removed it is recommended that the oil seal be replaced.

(1)

Measure shaft end play prior to the removal of cap

and record these readings. If end plate exceeds

.005 in. (0.127 mm) this indicates bearing wear.

(2)

If unit is full of oil, drain it into a clean drain pan.

Install drain plug and tighten.

(3)

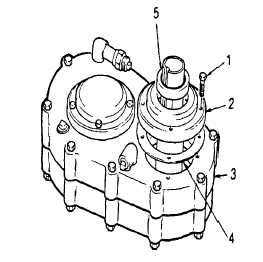

Remove four capscrews (1) that retain the cap (2) to

the housing (3).

(4)

Remove cap (2) from housing (3). The cap may be

loosened from the housing, by lightly tapping on the

corner of the cap. Never pry caps off because

damage may result.

(5)

Inspect bearing cone and caps for damage as

described in para. 2-7. If damage is evident refer to

OVERHAUL following. If there is no bearing

damage proceed to step 6.

(6)

Remove cap gaskets (4) using a putty knife. If

possible count and record the number of gaskets

removed.

2-86

|