|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

g.

Cylinder Block Deck Surface Inspection

(1) Check head contact area of block for flatness

with block straight edge and feeler gage.

(2) Block should not vary more than 0.003 in.

(0.008 mm) transversely or 0.006 in. (0.15

mm) longitudinally.

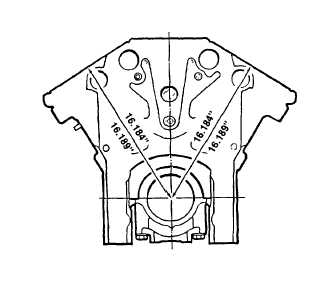

(3) Distance from centerline of crankshaft to top

of block/head surface must be between

16.184 in. and 16.189 in. (411.07 - 411.20

mm). If block is not within specification, it

must be replaced.

h.

Cylinder Counterbore Inspection

WARNING

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed

air for cleaning or drying unless the pressure Is/has been reduced to 30 psi (2.11 kg/cm2) or less. When

working with compressed air always use chip guards, eye protection and other personal protective

equipment.

(1)

Thoroughly clean cylinder liner counterbores. Blow area clean with compressed air.

(2)

Measure counterbore depth. Counterbore depth must be 0.4755 0.4770 in. (12.078 12.116 mm) or 0.4905

0.4920 in. (12.459 12.497 mm) and must not vary more than 0.0015 in. (0.038 mm) throughout the entire

circumference. There must not be over 0.0015 In. (0.038 mm) difference between any two adjacent cylinder

counterbores when measured along the cylinder longitudinal center line of the cylinder block.

j.

Block Bolt Hole Threads Inspection

(1) Inspect cylinder head and main bearing cap bolt holes. If threads are damaged, use a tap to clean up the

threads or Install a helicoil thread insert.

(2) An insert thread repair kit, J29513, is available for installing an 11/16 in. - 11 helicoil thread insert in the

cylinder head and main bearing cap retaining bolt holes of the cylinder block.

INSTALLATION

(1) Install all oil gallery and core hole plugs removed for cleaning procedure. Use pipe sealant (item 22,

Appendix B) on all threads.

(2) Use pipe sealant (item 22, Appendix B) on outer diameter of any cup plugs being installed. Always use

proper sized driver and pilot to fit cup plug. 2 1/2 in. plugs use driver J8092 and adapter J24597; 1 5/8 in.

plugs use driver J7079-02 and adapter J21850.

(3) Coat airbox bore plugs (2 1/2 - 16) with engine oil (item 17, Appendix B). Tighten to 270 ft lb (336 Nm) using

plug installer J23019.

3-189

|