|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

3-8.11

Cylinder Block - Continued

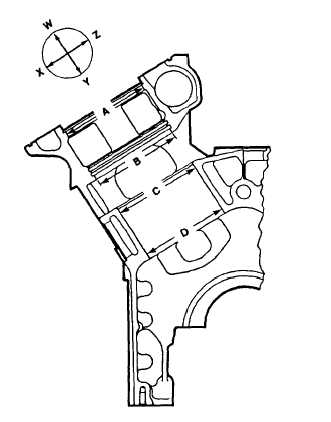

(3) Measure each cylinder bore at four locations as indicated by letters A, B, C, and D. Take two readings at

each location, 90 deg. to other as indicated by letters XZ and WY.

(4) The difference between the two readings at each level (out-of-round) must not exceed 0.0010 in. (0.030

mm).

NOTE

When measuring cylinder block bore, block should be flat on floor, main bearing caps installed and

tightened to a torque of 240 ft lb (325 Nm).

(5) Record the average of both readings taken at each level. These measurements must not exceed those

shown below. Taper between levels C and D must not exceed 0.0010 in. (0.030 in.)

Block

Maximum Allowable Average

Measurement at Location

A

B

C

D

New

5.3620 in.

5.3385 in.

5.2175 in.

5.2180 in.

136.195 mm

135.598 mm

132.525 mm

132.537 mm

Used

5.3635 in.

5.3395 in.

5.2185 in.

5.2185 in.

136.233 mm

135.623 mm

132.550 mm

132.550 mm

3-188

|