|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

NOTE

Four inserts are available to adjust liner height during installation.

Size

Thickness

Identification

(New Inserts)

std.

.1188 - .1193 in.

Black oxide or 2 purple stripes

std.

.1200 - .1205 in

No Color

std.

.1212 - .1217 in.

Copper or 2 orange stripes

+.015in.

.1362 - .1367 in.

White and orange stripe

(11) Mark liner and block with felt pen so liner may be reinstalled in same position in the same block bore.

(12) Remove cylinder liner hold down clamps.

b.

Piston Installation

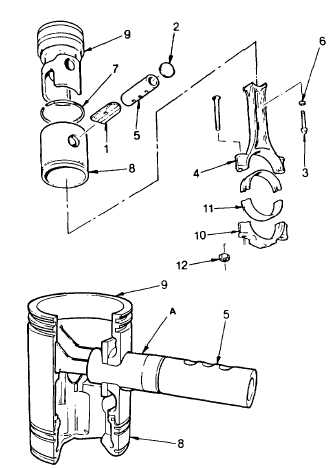

(1) Install bearing bushing (1) into the piston crown. It should slide in without force. It must be installed before

assembling piston skirt (8) to crown (9).

(2) Lubricate the metal seal ring (7) with engine

oil (Item 17, Appendix B) and install into

ring groove of crown with the chamfer

toward the bottom of piston.

(3) Compress

seal

ring

(7)

with

ring

compressor J24226.

(4) Push skirt (8) into position on the piston

crown (9)

(5) Place piston assembly resting crown down

on bench. Rotate skirt full 360 deg. on

crown. Seal ring must not bind or have any

tight spots. If seal ring sticks, remove tight

spots with flat file. Replace piston crown if

binding cannot be relieved.

(6) Lubricate piston pin (5) with engine oil (item

17, Appendix B). Line up the piston pin

opening in the piston skirt (8) with the

bearing opening in piston crown (9) with

alinement tool J24285 (A) to prevent

damage to pin (5) or bearing (1). Then

install piston pin.

3-169

|