|

| |

TM 5-4210-220-34

3-8.

ENGINE.

3-8.9

Piston, Liner, Rings, Rod and Rod Bearings.

This task covers

a.

Removal

b.

Inspection

c.

Installation

TOOLS

EQUIPMENT CONDITION

Shop Equipment, AutomotiveMain Engine Shutdown (see TM 5-4210-220-12)

Maintenance and Repair,

APU Shutdown (see TM 5-4210-220-12)

NSN 4910-00-754-0705

Batteries Disconnected (see TM 5-4210-220-12)

J8128 Ring Expander

Cab and Pump Body Head Shields Removed (see TM

J33048 Piston Disassembly Tool

5-4210-220-12)

J24599 Piston Ring Gage

Cooling System Drained (see LO 5-4210-220-12)

J28460 Reamer

Engine Oil Drained (see LO 5-4210-220-12)

J24563-A Sleeve Puller Set

Cylinder Head Removed (see para. 2-19.8)

J23059-01 Master Setting Gage

J5902-01 Cylinder Hone Set

MATERIALS/PARTS

J5347-B Cylinder Bore Gage

2, Appendix B Antifreeze

J24564 Master Ring Gage

4, Appendix B Antiseize Compound

J24565-02 Hold Down Clamp Set

10, Appendix B Dry Cleaning Solvent

J24898 Cylinder Liner Depth Gage

17, Appendix B Engine Oil

J24226 Piston Seal Ring

J24285 Piston Pin Alignment Tool

PERSONNEL REQUIRED - 2

J23762 Piston Pin Retainer Installer

J23987-01 Leak Detector

J5438-01 Feeler Gage Set

J24227 Ring Compressor

NOTE

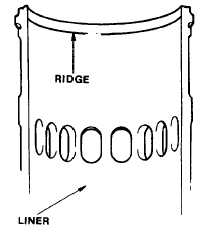

Piston and piston liners may be removed with engine in truck. The following instructions are written

assuming engine is in truck. REMOVAL

During disassembly of engine, tag and label all parts so related mating parts are identified for inspection and rebuild

procedure.

a.

Piston and Rod Removal

(1)

Remove oil pan as detailed in para. 2-

19.11.

(2)

Inspect bore of liner before removing

piston/rod assembly for wear ridge formed

at top of liner by the piston ring travel.

Ridge must be removed with cylinder ridge

reamer (e.g., Snap-On WR-25) to avoid

ring breakage and piston damage during

removal of piston/rod assembly.

(3)

Remove

rod

cap

retaining

nuts

(12),

bearing cap (10), and lower rod bearing

(11).

3-162

|