|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

INSPECTION

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s solvent) is potentially dangerous. Avoid repeated and prolonged

breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing equipment or other ignition

sources Always wear eye protection and protective clothing. The flash point of P-D-680 is 100 to 138 deg. F (30 to

59 deg. C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed air for

cleaning or drying unless the pressure is/has been reduced to 30 psi (2 11 kg/cm2) or less. When working with

compressed air always use chip guards, eye protection and other personal protective equipment.

(1)

Soak the camshafts in dry cleaning solvent (item 10, Appendix B).

(2)

Remove sludge or foreign material from camshaft oil gallery using a small wire brush.

(3)

Clean the camshaft exterior using dry cleaning solvent (Item 10, Appendix B) and dry using compressed air.

Blow oil gallery and oil holes using compressed air.

(4)

Inspect the cam lobes and journals for wear or scoring. If the cam lobes are scored, inspect the cam

followers as detailed in para. 2-19.4. Front and rear journal diameters should be 1.4970 to 1.4975 in.

(38.024 to 30.037 mm). Intermediate journal diameters should be 1.4980 to 1.4985 in. (38.049 - 38.062

mm).

(5)

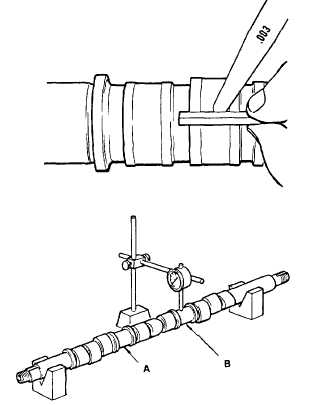

Using a tapered leaf set of feeler gages and

a piece of square hard material, measure

the flat on the injector rise side of the cam

lobes. If the flats measure less than 0.003

in. (0.008 mm) and there are no other

defects, the camshaft is satisfactory for

service. A slightly worn cam lobe, still

within acceptable limits, may be stoned and

smoothed over using fine crocus cloth (item

7, Appendix B).

(6)

Check

the

camshaft

runout

at

the

intermediate bearing surfaces (A and B)

with the camshaft mounted on V-blocks as

shown. Runout should not exceed 0.002 in.

(0.05 mm).

3-157

|