|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

NOTE

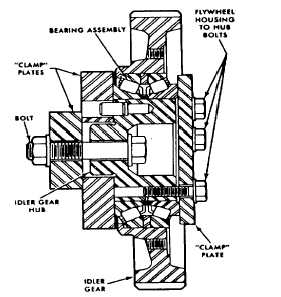

Prior to the installation of the idler gear assembly, bearing pre-load must be checked. Carry out steps 15 thru 26 to check

idler gear bearing pre-load.

(15)

Lubricate the idler gear bearings using engine oil (item 17, Appendix B) prior to pre-load testing.

(16)

Attach the two 3/4 in. bearing test fixture plates (11, Appendix D) to the Idler gear hub using a 1/2 in - 13 bolt,

washers and nut. Tighten the nut to 90 ft lb (122 Nm).

(17)

Attach the 3/8 in. bearing test fixture plate

(11, Appendix D) to idler gear hub using 3/8

in. - 16 capscrews. Tighten the capscrews

to 40 ft lb (54 Nm).

(18)

Clamp the idler gear assembly and fixture in

a vise.

(19)

Tie one end of a piece of lintless 1/8 in.

cord around a 1/8 in. round piece of wood.

Place the wood between two of the gear

teeth and rap the cord around the periphery

of the gear several times. Attach the other

end of the cord to a spring scale J8129.

(20)

Maintain a straight steady pull on the cord

and scale, 90 deg. to the axis of the hub,

and note the pull, in pounds and ounces,

required to start the gear rotating, Make

several checks to obtain an average

reading.

(21)

If the pull is within 1/2 lb minimum to 4 lbs maximum, and does not fluctuate more than 2 lb 11 oz., the idler

gear and bearing assembly is satisfactory for use. If the scale reading is within the 1/2 to 4 lb specified, but

fluctuates more than 2 lb 11 ounces, the idler gear and bearing assembly must NOT be installed on the

engine.

(22)

Fluctuations in scale reading may be caused by the cones not being concentric to each other, damaged

cones or rollers, or dirt or foreign material within the bearings. In these cases, the bearing should be

inspected for the cause of fluctuation in the scale readings and corrected or a new bearing installed.

(23)

A scale reading which exceeds the specified maximum indicates binding of the bearing rollers, or rollers

improperly installed.

(24)

When the scale reading is less than the specified minimum, the bearing is more likely worn and the bearing

should be replaced.

(25)

After the pre-load check is completed, remove the bearing test fixture plates (11, Appendix D) from the idler

gear assembly.

(26)

Attach the bearing retainer (2) to the Idler gear (3) using new capscrews (1). Tighten the capscrews to 29 ft

lb (39 Nm).

(27)

Attach the idler gear assembly as detailed in the INSTALLATION section preceding.

3-153

|