|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

b.

Idler Gear Repair

NOTE

While removing or installing an idler gear bearing, the bearing must be rotated to avoid the possibility of damaging

the bearing.

(1)

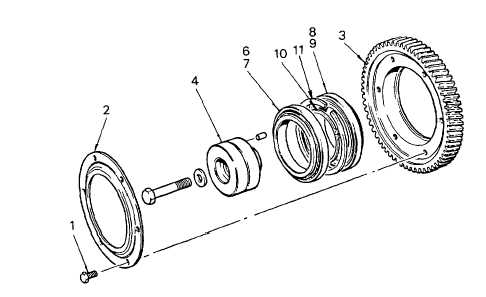

Remove the capscrews (1) that secure the bearing retainer (2) to the idler gear (3) and remove the bearing

retainer. Discard the capscrews, and replace with new ones.

(2)

Place the idler gear assembly in an arbor press, with the inner bearing cone supported on steel blocks. While

rotating the idler gear assembly, press the hub (4) out of the bearing.

NOTE

Idler gear bearings are matched sets; match-mark the bearings to ensure proper assembly.

(3)

Remove the gear assembly from the arbor press and remove the bearing cones (6 and 8) and spacer rings

(10 and 11).

(4)

Use the four notches provided around the shoulder of the gear (3) to access the bearing cups (7 and 9).

Using a brass drift and a hammer alternately tap the cups from the idler gear.

(5)

Carefully examine the bearings for wear, pitting, scoring or flat spots on the rollers or cones.

(6)

Check the idler gear hub to ensure that no chips or foreign material is deposited In the holes so as to cause

interference with the flywheel housing attaching bolts.

(7)

Examine the gear teeth for scoring, pitting or wear. If gear is damaged or worn, make sure the other gears in

the gear train are examined.

3-151

|