|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

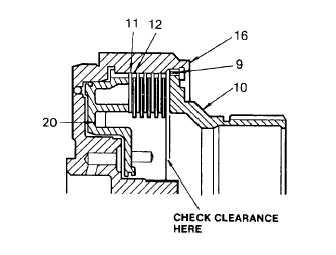

(33) Before completing the assembly, the clutch clearance must be established. Install forward piston (20) into

clutch housing (16).

(34) Beginning with an external-tanged plate, alternately install five external-tanged plates (11 ) and five internal-

splined plates (12) into forward-clutch housing (16).

WARNING

Do not install forward-clutch hub and

fourth-clutch driving hub into the fourth-

clutch housing assembly. Be sure the

forward-clutch hub and the fourth-clutch

driving hub are Installed into the forward-

clutch assembly. If these two hubs are

installed into the fourth-clutch housing

assembly by mistake, the transmission

will operate in reverse when the driver

selects any forward range.

(35) Install the fourth-clutch driving hub (10) into

housing (16) and retain it with snap ring (9).

(36) While holding hub (10) firmly against snap

ring (9), measure the clutch clearance with

gage J24192 at the location shown. When

clearance are satisfactory, the thinner step

of the gage

will enter between the driving hub and clutch plates; the thicker step will not. The prescribed clearance is

0.080 - 0.120 in. (2.03 - 3.05 mm).

(37) If the clutch clearance is not within the specified limits, remove snap ring (9), fourth-clutch driving hub (10)

and clutch plates (11) and (12). Replace clutch plates, as required, to obtain the desired clearance. Refer to

wear limits (Appendix C) to determine the plate thicknesses.

(38) When the clutch clearance is within the

specified limits of 0.080 0.120 (2.03 3.05

mm), remove snap ring (9) and hub (10),

clutch plates (11 and 12), and piston (20).

(39) Place piston on a work table with the return

spring

bosses

up.

Lubricate

with

transmission fluid (item 9, Appendix B) and

install two new lip-type teflon seal rings into

the inner and outer seal ring grooves in the

piston.

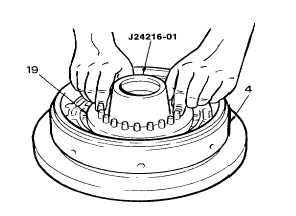

(40) Install seal ring protector J24216-01 onto

the clutch housing hub (4).

(41) Lubricate the piston seal rings with

transmission fluid (item 9, Appendix B) and centrally locate the piston (19) in the housing bore. Place the

piston and piston housing under an arbor press and apply pressure evenly until the piston is properly seated.

(42) f a press is not available, seat the piston in the housing bore by tapping the piston lightly with a mallet in a

continuous circular pattern until the piston is properly seated.

3-42

|