|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

NOTE

Valves, when installed dry, should move by their own weight,

(4) Install trimmer plug (7).

(5) Install springs (4 and 5), valve stop (6), and retainer plug (2).

(6) Compress springs (4 and 5) and install retainer pin (3) to secure plug (2).

n.

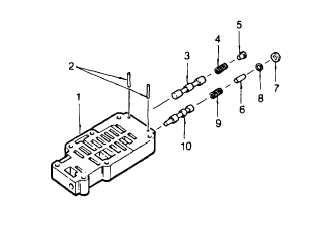

Low Shift Valve Inspection, Repair And Assembly

(1) Depress valve stop (5) against its spring

and remove retainer pin (2).

(2) Release spring pressure and remove valve

stop (5), spring (4) and relay valve (3).

NOTE

Note position of adjusting ring (7) in

relation

to

retainer

pin

(2)

before

removal.

(3)

Depress adjusting ring (7) against its spring

and remove retainer pin (2).

(4) Remove adjusting ring (7), washer (8), valve stop (6), spring (9), and valve (10).

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s solvent) is potentially dangerous. Avoid repeated and

prolonged breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing

equipment or other ignition sources. Always wear eye protection and protective clothing. The flash point

of P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

(5) Inspect and clean parts with dry cleaning solvent (item 10, Appendix B). Replace any damaged parts.

NOTE

Valves, when installed dry, should move by their own weight.

(6) Install valve (10) into valve body (1).

(7) Install spring (9), valve stop (6), washer (8), and adjusting ring (7). Aline the hole in valve stop (6) with the pin

hole in valve body (1). Position the adjusting ring in the same position as it was before removal.

(8) Press inward against adjusting ring (7) until retainer pin (2) can be installed.

3-23

|