|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

NOTE

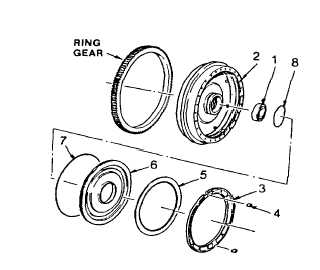

If bearing (1) shows signs of excessive wear or damage, it must be replaced.

(4)

Install seal ring (8) onto the flywheel hub, and seal ring (7) onto the outside diameter of lockup clutch piston

(6). Lubricate both seal rings with petroleum jelly (item 21, Appendix B).

(5)

Place a pencil mark on the edge of the

lockup clutch piston opposite a dowel pin

hole. Also place a pencil mark in the

flywheel bore, opposite a dowel pin.

(6)

Install the lockup clutch piston into the

flywheel, alining the pencil marks, to

engage the recesses in the piston with the

dowel pin. Be certain the dowel pins are

engaged.

(7)

Install the lock keys (4) in the lock key

grooves of the flywheel. Use petroleum

jelly (item 21, Appendix B) to retain them.

(8)

Install the lockup clutch plate (5).

(9)

Install the lockup clutch backplate (3) flat side first, engaging the notches in the plate with the keys (4) in the

flywheel.

(10) Carefully center the lockup clutch plate in the flywheel. Install the torque converter turbine (9), engaging its

hub splines with the internal splines of the lockup clutch plate.

(11) Flywheel, lockup clutch, and turbine are now assembled and ready for final installation.

f.

Disassembly And Repair Of Torque Converter Stator Assembly

(1)

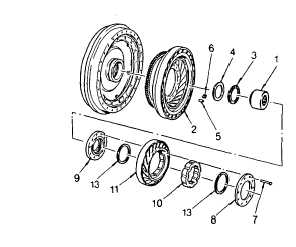

Rotate stator freewheel roller race (1) in a

clockwise direction to free it for removal

from the stator (2).

(2)

Remove race (1), thrust bearing (3), thrust

bearing race (4), ten stator rollers (5), and

ten freewheel roller springs (6) from stator

assembly (2).

NOTE

Do not disassemble the stator assembly

unless replacement of stator thrust

washer (9), rivets (7), or washer (8) is

necessary. If stator (11) or cam (10) is

cracked

or

damaged,

replace

the

complete stator assembly.

A hydraulic press having a minimum capacity of five tons, an adjustable table, and a pressure gage, to assist in

determining the rivet staking load, is required to rebuild the stator assembly.

3-15

|