|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

2-21.2

Differential Carrier - Continued

(3)

At teeth side of ring gear, tighten adjustor

until it contacts the bearing cup. Continue

tightening adjustor two or three notches and

this will preload bearings and provide

backlash.

(4)

Measure backlash with a dial indicator.

Used

Gear

Ring

Reset

to

backlash

recorded before disassembly. New Gear

Ring Backlash should be 0.006 0.016 in.

(0.15 0.41 mm). If backlash is incorrect,

proceed as described below to readjust.

(5)

To add backlash: Loosen the adjustor on

the teeth side of the ring gear several

notches. Loosen the opposite adjustor one

notch. See illustration for definition. Return

to adjustor on teeth side of the ring gear

and tighten adjustor until it contacts the

bearing cup. Continue tightening the same

adjustor 2 or 3 notches. Recheck backlash.

(6)

To remove backlash: Loosen the adjustor

on the teeth side of the ring gear several

notches. Tighten the opposite adjustor one

notch. Return to adjustor on teeth side of

ring gear and tighten adjustor until it

contacts the bearing cup. Continue

tightening the same adjustor 2 or 3

notches. Recheck backlash.

b.

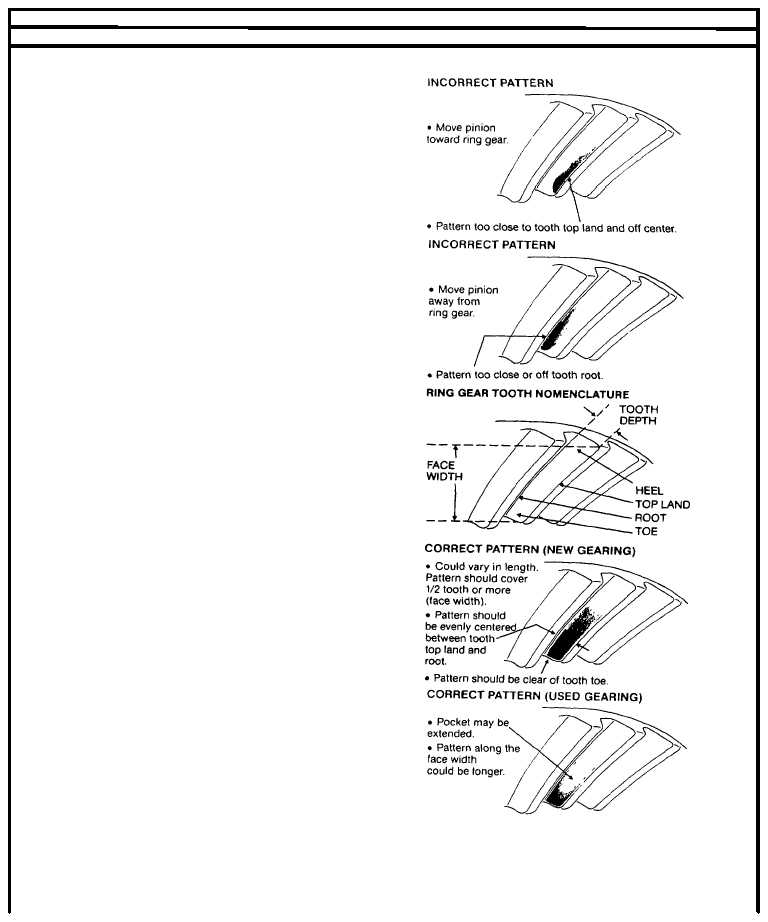

Ring Gear And Pinion Tooth Contact Adjustment

(1)

Check tooth contact pattern (new gear).

Paint twelve ring gear teeth with marking

compound and roll the gear to obtain a

contact pattern. The correct pattern is well-

centered on the ring gear tooth within

lengthwise contact clear of the toe. The

length of the pattern in an unloaded

condition is approximately one-half to two-

thirds of the ring gear tooth. If adjustment

Is necessary proceed to step 3.

(2)

Check tooth contact pattern (used gear).

Used gearing will not usually display the

square, even contact pattern found in new

gear sets. The gear will normally have a

"pocket" at the toe-end of the gear tooth

which tails into a contact line along the root

of tooth. The more use a gear has had, the

more the line becomes the dominant

characteristic of the pattern. Adjust used

gear sets to display the same contact

pattern observed before disassembly. A

correct pattern is clear of the toe and

centers evenly along the face width

between the top land and root. Otherwise, the length and shape of the pattern are highly variable and is considered

acceptable as long as it does not run off the tooth at any point.

2-298

|