|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

NOTE

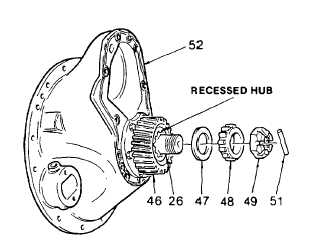

Carry out step 3 even if bearing (48) only

needs replacement.

(3)

Remove bearing cone (48), spacer (47),

and gear (46) in one operation using a

suitable puller as shown.

(4)

Install gear (46) on pinion (26). Be sure

recessed hub is facing out as shown.

(5)

Install spacer (47) and bearing (48). Use a

hammer and a suitable sleeve to seat

bearing.

(6)

Install castle nut (49) and tighten to 840 ft lb

(1140 Nm). Continue to tighten nut further

until a roll pin hole in pinion alines with a

slot in castle nut.

(7)

Install roll pin (51).

(8)

Proceed with installation of power divider as

detailed in para. 2-20.1.

ADJUSTMENT

NOTE

Bearing preload adjustment Is performed for both pinion and differential bearings. It maintains proper

gear alinement by creating correct bearing cone and cup relationship for free rotation under load. The

pinion pilot bearing does not require a preload adjustment.

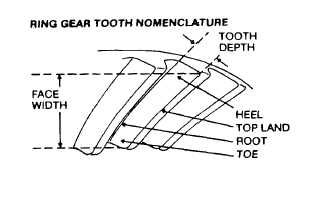

Ring gear tooth contact adjustment positions ring gear and pinion for best contact under load Correct

adjustment distributes torque evenly over gear teeth and helps maximize gear set life.

a.

Differential Bearing Preload And Ring Gear Backlash Adjustment

(1)

Loosen the bearing adjustor on the same

side as, the ring gear teeth until its first

thread is visible.

(2)

Tighten

the

bearing

adjustor

on

the

backface side of the ring gear until there is

no backlash. This can be tested by facing

the ring gear away from the body while

gently rocking the gear from side to side.

There should be no free movement. Rotate

the ring gear and check for any point where

the gear may bind. If such a point exists,

loosen and retighten the back side adjustor.

Make all further adjustments from the point

of tightest mesh.

2-297

|