|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

2-21.1 Ball Socket Assembly - Continued

NOTE

Upper kingpin bearing has a smaller diameter bearing cone and a thicker wall bearing cup compared to

lower kingpin bearing.

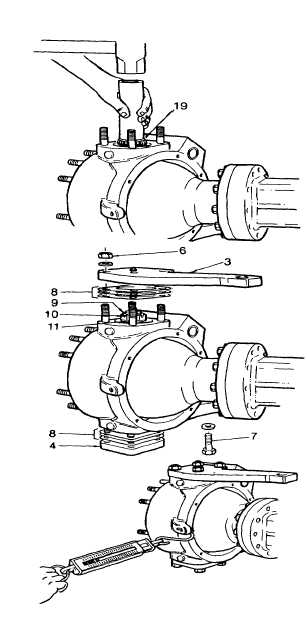

(5)

Install upper and lower kingpin bearing

cones (20 and 19). Be sure correct

bearings are used with upper and lower

pins. Drive each bearing cone in place

using a suitable arbor and hammer. Be

sure sleeve only contacts bearing race and

not roller cage.

(6)

If removed, install upper and lower bearing

cups using a suitable arbor and hammer.

Tap bearing cups into ball socket until flush

with the kingpin cover surfaces.

(7)

Install washer (11) and nut (10) on kingpins

(12 and 13). Tighten nuts to 500 ft lb (680

Nm). If needed, tighten nuts further to line

up holes in kingpins with slots in nuts.

Install and secure cotter pins (9).

NOTE

Shims 0.003, 0.005, and 0.020 in. (0.08,

0.13, and 0.51 mm) in thickness, are

used between kingpin covers and ball

socket.

If

new

components

are

assembled, a shim pack of 0.045 in.

(1.14 mm) should be used under each

kingpin cover. If existing components

are reassembled, use either original

shim packs or new shim packs equal to

the original packs in thickness.

(8)

Install kingpin covers (3 and 4) together

with shims packs (8). Make sure ball

socket is centered on axle ball by using

shim packs of same thickness. If different,

exchange shims between packs until even

thickness is achieved. Tighten cover nuts

(6) to 360 ft lb (490 Nm) and capscrews (7)

to 220 ft lb (300 Nm).

(9)

Lubricate upper and lower kingpin bearings

with

grease

(item

16,

Appendix

B).

Lubricate until grease can be seen coming

out of bearing cones.

(10) Remove

kingpin

spreading

fixture.

2-284

|