|

| |

TM 5-4210-220-34

2-20.

REAR AXLE - Continued

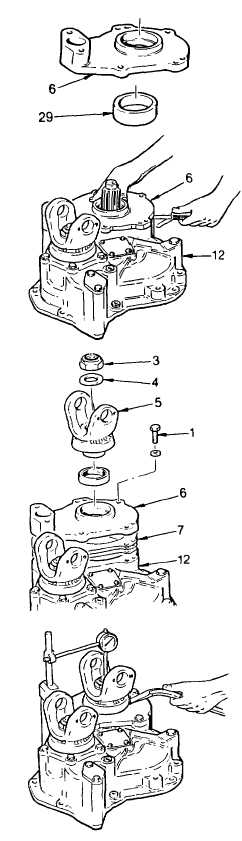

(4)

Press bearing cone (29) onto shaft (9).

Be sure to use an arbor which only

contacts the bearing race and not the

bearing rollers.

(5)

Install bearing cup (29) in cover (6)

using a press and suitable arbor. Be

sure cup is

fully

seated

against

shoulder inside cover.

(6)

Install assembled shaft (9) in power

divider cover (12) but do not install

shift fork.

(7)

Place cover (6) in assembly position

with power divider cover (12) as

shown. Hold cover in position by hand

and measure clearance between the

covers using a feeler gage. The

measured clearance plus 0.005 in.

(0.13 mm) equals the thickness of the

initial shim pack.

NOTE

To ensure proper output shaft end play,

necessary shimming of cover (6) must

be calculated and checked. To do this,

carry out step 8 thru 10. Repeat these

steps as necessary until correct end play

is obtained.

(8)

Install bearing cover (6) with a shim

pack of calculated thickness. Fasten

cover (6) to cover (12) using four

capscrews

(1)

and

lockwashers

installed around shaft (9). Tighten

capscrews to 125 ft lb (170 Nm).

Install yoke (5), washer (4), and nut

(3). Tighten nut snugly.

(9)

Using a dial indicator, check output

shaft end play as shown. End play

should be in the range of 0.003 to

0.007

in.

(0.08

to

0.18

mm).

Calculate shim thickness to be added

to or deleted from the installed shim

pack (7).

(10) Remove yoke (5) and cover (6).

Adjust shim pack as required by

calculation in previous step. Install

cover and yoke, and recheck end play.

(11) Remove yoke and cover and install

shift fork 431) on sliding clutch.

(12) Install spacer (28) and oil seal (27) in

cover (6). Be sure the open side of

seal faces inwards. Use a suitable

arbor to drive seal in place.

2-273

|