|

| |

TM 5-4210-220-34

2-20.

REAR AXLE - Continued

2-20.1 Power Divider (Transfer) Unit - Continued

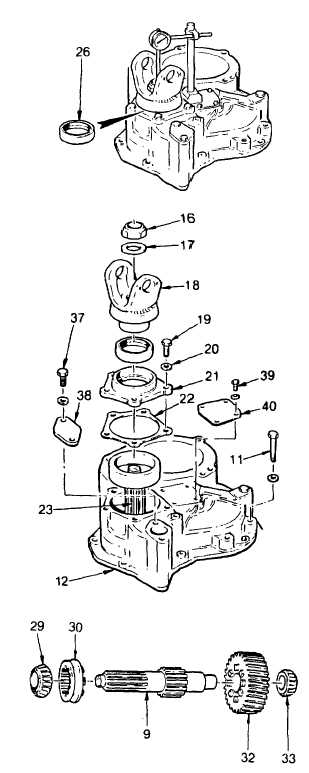

(16) Using a dial indicator, check input shaft

end play as shown. End play should

be 0.003 to 0.007 in. (0.08 to 0.18

mm) when all new parts are used;

0.013 to 0.017 in. (0.33 to 0.43 mm)

when parts are reused.

(17) Calculate the thickness of the shims to

be added to or deleted from the shim

pack (22).

(18) Remove yoke (18) and cap (21).

Adjust shim pack as required by

calculation in previous step.

(19) Reinstall cap (21) and yoke (18) as

detailed in step 14 and 15 and check

end play as detailed in step 16.

Repeat steps until correct end play is

obtained.

(20) When end play is correct, remove yoke

and install oil seal (26) using a suitable

arbor and a hammer. Be sure the

spring side of seal faces inward.

(21) Install yoke (18), washer (17), and nut

(16). Tighten nut firmly.

b.

Output Shaft Installation

NOTE

Proceed

to

step

6

of

installation

procedure if none of the parts making up

the output shaft assembly have been

replaced.

(1)

Mount output shaft (9) in a press with

yoke splines facing down. Install gear

(32) on shaft with clutch teeth facing

down.

(2)

Install bearing cone (33). Be sure

bearing cone seats completely against

shoulder on output shaft. To prevent

bearing damage, use an arbor that

only contacts the bearing race.

(3)

Check that gear (32) can rotate freely

on output shaft. Place sliding clutch (30) with clutch

teeth facing gear (32) on the other end of the shaft.

2-272

|