|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.12

Throttle, Fuel Shutdown, And Fire Pump Governor - Continued

c.

Pump Governor Adjustment.

NOTE

Mechanical Governor, fuel shutdown and foot throttle chamber must be adjusted and the engine idle and maximum

rpm must be set prior to carrying out pump governor adjust.

(1)

Be sure pump governor has been installed as in REPLACEMENT following. This procedure ensures the

assembly itself is adjusted correctly.

(2)

With

engine

shutdown,

rotate

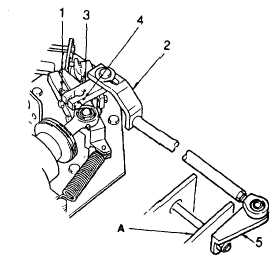

pump

governor arm (3) counterclockwise until the

pivot bolt is against the outer end of the slot

of the pump governor link (4).

(3)

Be sure bracket (5) on pump governor shaft

is held to the left near bracket (A) and then

tighten locking nut and bolt (1 and 2) on the

pump governor arm.

(4)

Start main engine and start fire pump in

structural mode. Be sure pump is flooded.

Using hand throttle on structural control

panel adjust engine speed so that pump

pressure increases to 150 psi (1034 kPa).

Be sure pump pressure is stable. Open

various

discharges

and

check

pump

pressure restabilizes to this pressure. Shut

pump down.

(5)

Set pump to CFR mode and start pump. Switch on governor and check pump pressure increase to 250 psi

(1720 kPa). If pressure exceeds 280 psi (1930 kPa) switch off pump governor immediately. Reduce

pressure as detailed in following steps.

(6)

With pump pressure stabilized, adjust pressure to 250 psi (1720 kPa) using air control valve mounted on

service brake plate.

(7)

Open bumper turret and roof turret in turn and check pressure restabilizes to 250 psi (1720 kPa) after each

operation.

REPLACEMENT

a.

Fuel Shutdown Replacement

NOTE

If a new engine is being prepared for installation carry out all instructions.

If the fuel shutdown is being removed and installed on engine(s) already in service start at instruction 3.

2-242

|