|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

(5)

Be sure that ’when electrical connection is made, air is exhausted from the solenoid and the plunger retracts.

(6)

Be sure that when 12-Vdc supply is removed, the plunger extends. Replace whole assembly if plunger fails.

See REPLACEMENT following.

(7)

Reconnect electrical supply to place solenoid in engine run position, cylinder retracted.

(8)

Install arm (2) and aline it with the plunger ensuring it rests against the plunger. Tighten screw (1) firmly.

(9)

Disconnect electrical supply, and check all fuel injectors are in the no-fuel position (injector control rack fully

withdrawn).

(10)

Adjust arm (2) as required. The Injector racks must be fully withdrawn and checked to go to that position

whenever the engine ignition is set to OFF.

b.

Foot Throttle Chamber Adjustment

NOTE

Engine must be shutdown.

Exhaust valve clearance, injector timing, mechanical governor and injector control racks must be set before

adjusting the throttle.

(1)

Ensure air tanks are pressurized. If no air,

pressurize using shop connection on left

side of pump body. Check all air tanks are

at 100 psi (690 kPa).

(2)

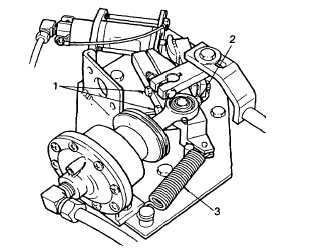

Check screws (1) and nuts (2) on throttle

arm are loose.

(3)

Press and release foot throttle in cab a few

times and ensure throttle chamber rod

moves

freely.

Check

spring

(3)

is

connected and pulls throttle arm promptly

back when throttle pedal is released.

(4)

With engine shut down, release foot throttle

in cab.

(5)

Tighten clamp screws (1) and nuts (2).

(6)

Depress foot throttle up and down a few times to check operation of the foot throttle and the governor speed

shaft.

(7)

With the foot throttle depressed, and the rocker covers removed, see para. 2-19.3, check that fuel injectors

are in the full-fuel position (injector control rack fully in).

2-241

|