|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

(43)

Slippage of impeller or gear should not occur at this torque.

(44)

If slippage is felt, remove pump assembly from vise and examine the scribe marks. Determine whether the

gear or impeller turned on shaft. In either case, the shaft must be replaced along with the component that

turned.

(45)

After replacing necessary parts, retest the water pump assembly for slippage

(46)

Insert a feeler gage into the water outlet opening of the pump. The clearance between the impeller and the

pump body must be a minimum of 0.015 in. (0.38 mm). Repair or replace pump assembly to obtain desired

clearance.

(47)

If pump is to be stored after rebuild, carry out steps 48 and 49. If it is to be installed on the engine, see

INSTALLATION preceding.

(48)

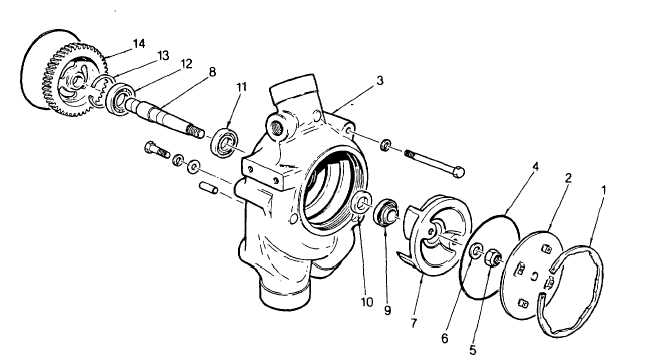

Install new cover seal ring using grease (item 16, Appendix B) in groove and on seal ring.

(49)

Install cover securely in place with snap ring.

2-227

|