|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.8

Cylinder Head - Continued

(10) Place new seal rings in the counter bores of the water and oil holes in the cylinder block (13 rings altogether).

(11) Install a new oil seal in the groove around the perimeter of the cylinder block with the colored stripe facing

away from the cylinder bores. Be sure seal lays flat in the groove and is not twisted or stretched when

installed.

(12) Install guide studs J24748 in the two outboard bolt holes in the cylinder block.

(13) Attach lifting tool J22062-01 to the cylinder head, if convenient, then position head above the cylinder head.

(14) Make final visual check to be sure all seals, gaskets, and shims are in place.

(15) Wipe the bottom of the head clean and lower head over guide studs onto the surface of the block.

(16) Apply

a

small

amount

of

antiseize

compound (item 4, Appendix B) to the

threads and to the underside of each

cylinder head bolt head.

(17) Install bolts on the cam shaft side first to

take up the tension on the push rod

springs. Remove the guide studs and lifting

fixture and install all remaining bolts.

Tighten all bolts to 20 ft lb (27 Nm).

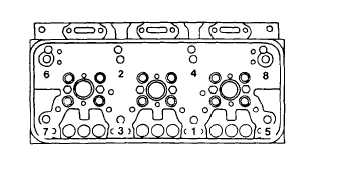

(18) Tighten the bolts in 50 ft lb (68 Nm)

increments in the sequence shown until all

bolts are at 240 ft lb (325 Nm). Hold the

tension for 2 3 seconds to allow bolt to

move under this torque.

REPAIR

a.

Water Nozzle Repair

NOTE

Replace the nozzles if they are loose in the cylinder head. If the engine has overheated, replace all

nozzles.

(1) Pry out the old water nozzles.

(2) Be sure the water inlet ports in the cylinder head are clean and free of scale. Use a soft bristle brush to clean

the holes. Do not use a drill bit as the holes are reamed for fit.

(3) Place cylinder head on an arbor press, fire deck side up. Be sure bottom side of head is supported on its rim

to prevent damage to valve guides etc.

(4) Aline new nozzle in hole and using a suitable arbor, press into position.

(5) Check nozzles are recessed from flush to 0.015 in. (0.38 mm) below the fire deck.

2-218 (2-219 Blank)

TM 5-4210-220-34

|