|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.8

Cylinder Head - Continued

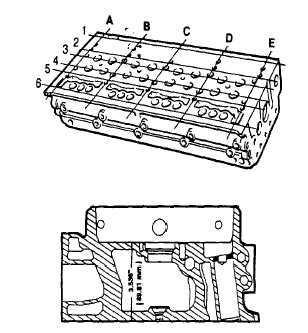

(4) Using a heavy accurate straight edge and feeler

gage J3172, check for longitudinal and transverse

warpage of the head as shown. The maximum

longitudinal warpage allowable is 0.0055 in. (0.140

mm); the maximum transverse warpage allowable is

0.0040 in. (0.102 mm).

To prevent failure of an engine when rebuilt, do not

remove more metal from the fire deck of any cylinder

head below the minimum distance of 3.536 in. (89.81

mm).

(5) The cylinder head may be refaced provided the

injector tubes are removed prior to machining. The

water nozzles may remain in the head.

(6)

After refacing the head, the protrusion of valve seat

inserts (2-19.7), exhaust valves (2-19.7), injector

tubes (2-19.5) injector spray tip spray tips (2-19.5),

and push rods (2-19.4) must be checked and corrected. The water nozzle bores must also be deburred.

(7) Inspect the exhaust valve seat inserts and the valve guides as detailed in 2-19.7.

(8) Inspect the cam follower bores in the cylinder head for scoring or wear. Light score marks may be cleaned

up with emery cloth (item 13, Appendix B).

(9) Measure the diameter of the cam followers with a micrometer and compare with similar readings for each

bore. The follower cylinder head clearance must not exceed 0.006 in. (0.15 mm) with used parts. If the

bores are excessively worn or scored replace the cylinder head.

(10) Check the water hole nozzles for looseness. Replace nozzles if loose as detailed in REPAIR following.

(11) Replace broken or damaged studs. Apply threadlock liquid (item 29, Appendix B) to the new studs. Install

and torque to 40 ft lb (54 Nm).

(12) Inspect the pilot sleeves in the cylinder head bolt holes at each end of the head on the camshaft

side. Replace any damaged or loose sleeves using an arbor press (these sleeves are installed

to provide a close fit for the cylinder head bolts used when installing the head on the engine).

(13) If injectors are removed, remove all cylinder head

to-fuel pipe connectors and inspect for damaged

threads. Remove all seals and discard.

(14) Coat all plugs that were removed cleaning for with

pipe sealant (item Appendix B) and install. Tighten

to the following torques.

NPT Size

Recommended Torque

1/8-27

12 ft lb

(16 Nm)

1/4-18

16 ft lb

(22 Nm)

3/8-18

22 ft lb

(30 Nm)

1/2-14

27 ft lb

(37 Nm)

3/4-14

37 ft lb

(50 Nm)

2-216

|