|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

(16) Aline the fuel pipes and connect them to the injectors and fuel connectors. Tighten the fuel pipe nuts to

12 ft lb (16 Nm) torque using socket J8932-01.

NOTE

Do not bend the fuel pipes and do not exceed the specified torque. Excessive tightening will twist or

fracture the flared ends of the fuel pipes and result in leaks. Lubricating oil diluted by fuel oil can cause

serious damage to the engine bearings.

(17) Fill the cooling system if It was drained.

(18) Adjust the exhaust valve clearance see para. 2-19.7 and time the injectors see para. 2-19.5.

(19) Replace rocker covers see para. 2-19.3.

REPAIR

NOTE

Repair of all components except cam follower consists of replacement of failed components as detailed in

INSPECTION preceding.

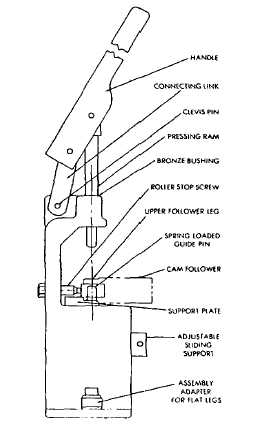

Cam Follower Repair

CAUTION

Do not attempt to bore out the legs of a standard cam follower for an oversize pin. Use tool J33421 for

cam follower roller replacement.

(1)

Pull the adjustable sliding support out against

its stop on tool J33421.

(2)

Place the cam follower with follower pin resting

on the spring loaded guide pin in the fixture.

(3)

Push the follower down until the lower leg engages the

slot in the support plate. This supports the roller which

in turn supports the upper follower leg.

(4)

Push the follower in until contact is made with

the roller stop screw. This should put the roller

pin in alinement with the pressing ram.

(5)

Lower the handle to put pressure on the roller

pin.

(6)

Push the adjustable sliding support in until

resistance is felt. This causes the lower

follower leg to be supported.

2-178

|