|

| |

TM 5-4210-220-34

2-17.

FUEL TANK.

This task covers:

Repair

TOOLS

EQUIPMENT CONDITION

Shop Equipment, Automotive

Fuel Tank Removed From Truck

Maintenance and Repair,

(see TM 5-4210-220-12)

NSN 4910-00-754-0705

Fuel Priming Pump Removed From Tank

(see TM 5-4210-220-12)

WARNING

Diesel fuel is flammable. Diesel tank must be steamed out before any repair is attempted.

NOTE

Fuel tank is fabricated from 0 188 in. and 0.125 in. 5052 H32 aluminum.

REPAIR

(1) Remove breather from fuel tank. Blank the flange openings with a temporary cap.

(2) Steam fuel tank for at least 8 hours at a pressure of at least 5 psi (35 kPa).

WARNING

Personal injury may be sustained from rupture of the tank if it is over-pressurized. Do not apply

more than 12 psi (85 kPa) air pressure when testing.

(3) Inspect fuel tank for leaks and determine exact location. If the leak is small, pressurizing the tank with 1 - 2

psi (7 - 14 kPa) air may help to find the leak. Brush a soap solution on outside of tank. Bubbles indicate

location of leak.

(4) Only small leaks should be repaired. Any split or puncture creating a hole or crack more than 2 in. (5 cm)

long should not be repaired. Replace the tank as detailed in TM 5-4210-220-12.

(5) To weld any holes, see TM 9-237.

(6) The following types of welds may be

attempted.

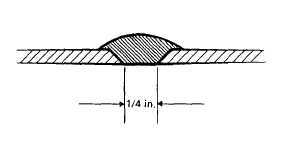

(a) Small hole leaks (less than 1/4 in. (6

mm)): Clean out hole using file or

countersinking bit. Roughen up area

around the hole. Fill hole with welding

rod and extend weld out at least 1/8 in.

(3 mm) to surrounding area. Do not

level weld.

2-154

|