|

| |

TM 5-4210-220-12

4-32. FRONT AXLE-Continued

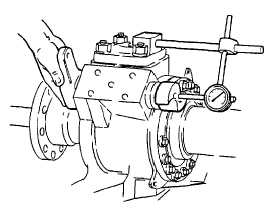

(9)

Push

camshaft

outward

and

note

maximum

dial

indication. The end play measured should be 0.005 -

0.045 in. (0.13 - 1.14 mm).

(10)

If

end

play

is

outside

these

limits

adjust

by

removing/installing shim washers (12) between slack

adjuster and lock ring.

NOTE

Shim washers are available in two thicknesses, 0.030 in.

(0.76 mm) and 0.060 in. (1.52 mm).

(11)

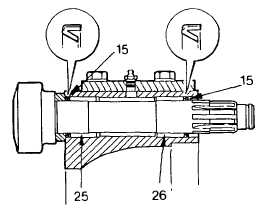

Check that inside surfaces of bushings (25 and 26) are

smooth. If rough, replace bushings and oils seals.

Bushings can be removed with a suitable puller.

(12)

Mount a suitable dial indicator with the plunger

referencing the cam face at 90 deg. to cam bearing

journal.

(13)

Set indicator dial to zero and move cam head radially up

and down. Note maximum dial reading.

(14)

Mount dial indicator at slack adjuster end of camshaft and

repeat step 13.

(15)

If measured play exceeds 0.02 in. (0.51 mm) at either end of camshaft, replace bushings (25 and 26).

(16)

Recheck radial play, as above, when new bushings are installed in ball socket bore. If play still exceeds

0.020 in. (0.51 mm), replace camshaft

(17)

Check camshaft oil seals (15) for wear and damage. If oil seal lips are distorted or damaged, or new

bushings (25 and 26) have been installed in ball socket, replace oil seals. Be sure seal springs are facing

in the same direction, away from the brake spider.

(18)

Inspect slack adjuster (14) for damage to body, splines, and clevis pin bushings. If any serious defects

are noticed, replace slack adjuster.

4-607

|